Birla Carbon, a manufacturer of carbon black solutions, has embarked on a collaborative project to develop biocrude-derived graphite for lithium-ion batteries.

The company has collaborated with NC State University, the National Renewable Energy Laboratory (NREL), Ensyn, The Battery Innovation Center (BIC), and Yale University to develop and scale up the production of biocrude-derived graphite.

“As a key player in this collaboration project, Birla Carbon will convert the biocrude-derived coke to battery-grade graphite using a new-to-the-world graphitization technology, which greatly improves the sustainability of battery materials production by both increasing product output and decreasing energy usage, said Dr. Ann Schoeb, Chief Research and Development Officer, Birla Carbon.

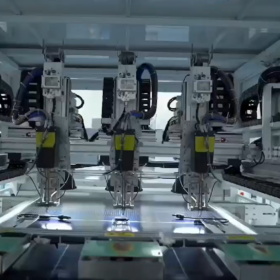

Birla Carbon will purportedly perform graphitization utilizing existing equipment at its facility, where it processes carbon products as part of its regular course of business.

The project aims to produce graphite more sustainably using renewable feedstocks and aligns with Birla Carbon’s goal to reach net-zero carbon emissions by 2050.

The increase in demand for electric vehicles is primarily fueling the lithium-ion battery market, and portable electronic devices, power tools, residential energy storage, and grid-level storage applications are becoming increasingly dependent on this technology.

Graphite is one of the materials in a lithium-ion battery that stores lithium. Producing battery-grade graphite from biocrude offers a more sustainable pathway toward producing these valuable materials.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.