VGF incentive cut may raise BESS tariffs by 10%, but impact likely temporary: SBICAPS

A new report by SBICAPS anticipates that the incentive cut under the second phase of the viability gap funding (VGF) scheme for standalone battery energy storage systems (BESS) could lead to a tariff increase of around 10%. However, it adds, this increase is manageable and could be absorbed in the coming months as capex costs continue to decline.

The rise of cell-to-pack technology: What it means for two- and three-wheelers in India

India is home to one of the largest markets for two- and three-wheelers globally, and these segments play a crucial role in urban mobility, last-mile delivery, and short-distance logistics. However, current electric variants often face challenges related to weight, range, and cost—all of which cell-to-pack (CTP) technology addresses directly.

From trash to treasure: Is India ready for battery recycling revolution?

Given the demand and the unavailability of Lithium, Nickel, Cobalt, Manganese, and Rare Earth Elements (REEs) in sufficient quantities, as a nation, we may be staring at a scenario we had with crude.

Why LFP batteries are gaining traction in India’s EV ecosystem

Leading EV manufacturers and battery suppliers in India are increasingly adopting Lithium Iron Phosphate (LFP) battery technology for entry-level and mid-range EVs. This is due to a balance of cost, safety, and durability that fits the Indian market’s practical needs.

Why battery design is one of the core challenges for recycling companies?

While transitioning to renewable energy and widespread adoption of batteries is a must, recycling cannot be an afterthought. It must be built into design and supply chain decisions.

MIT-WPU launches battery research center focused on advanced Li-ion and Na-ion technologies

The facility supports comprehensive end-to-end battery development, from active material synthesis to coin cell fabrication, and electrochemical performance evaluation.

Propagation of lithium-ion fires is the real threat

Live fire tests aim to demonstrate physical containment technology.

Falling Li-ion battery prices mirror solar photovoltaics trends: Is there a role for second-life batteries before recycling?

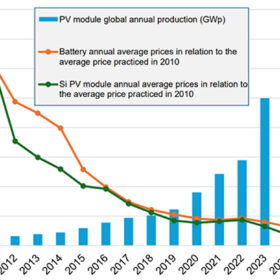

Lithium-ion batteries are everywhere, powering everything from consumer electronics to electric vehicles, residential PV storage systems, and, more recently, mitigating curtailment in large-scale wind and solar power plants. EVs are driving large-scale demand for Li-ion batteries which will result in substantial volumes of spent batteries in the near future. This scenario highlights the potential for repurposing EV batteries for second-life stationary applications, which could maximise their value before recycling. However, to fully realise this opportunity, several economic, technical, and regulatory challenges must be addressed and resolved.

Falling prices, rising geopolitical risks define energy storage scenarios

Experts speaking at the upcoming NetZero Milan Expo-Summit 2025 have told pv magazine that lithium’s rising competitiveness is pressuring emerging chemistries like sodium-ion, as the market shifts from incremental gains to larger cells that could reshape enclosure design.

BC Jindal Group announces INR 15,000-crore investment in solar and battery manufacturing

The BC Jindal Group has unveiled plans to invest INR 15,000 crore by 2030 to establish multigigawatt-scale manufacturing capacities for solar cells and modules, battery cells and packs, and solar glass.