Photovoltaics for atmospheric water harvesting

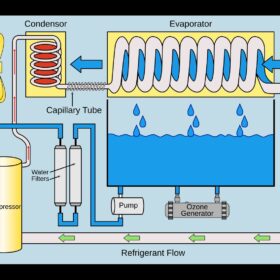

A scientist in Turkey has simulated eight PV-supported hybrid atmospheric water harvesting systems and compared their performances. They were all considered to operate with R1233zd(E), R1234yf, and R600a, as well as R32 refrigerants. The required PV system size was as low as 20 m2.

Solarium, NISE sign MoU to develop solar-based heating solutions for cold regions

Solarium Green Energy Ltd has signed a Memorandum of Understanding (MoU) with the National Institute of Solar Energy (NISE), under the Ministry of New and Renewable Energy, to jointly develop advanced solar-based heating technologies.

Indian researchers develop fast-charging sodium-ion battery, promising over 3,000 cycles

NAtrium Super Ionic CONductor (NASICON) materials continue to show their potential for sodium-ion anodes in high-performance batteries, with fresh research out of India delving more into the materials.

SolarEdge expands India operations with new R&D and technology center in Bengaluru

SolarEdge Technologies, an Israel-based solar inverter and battery energy storage specialist, has inaugurated a new state-of-the-art R&D and Technology Center in Bengaluru. The facility will play a key role in supporting SolarEdge’s global innovation pipeline while addressing the unique needs of the Indian market.

All solar cell efficiencies at a glance – updated

The research group led by Professor Martin Green has published Version 66 of the solar cell efficiency tables. There are 17 new results reported in the new version.

Sekisui, TNO exploring perovskite solar PV collaboration

Japan’s Sekisui Solar Film and the Netherlands’ TNO have signed a letter of intent to explore collaborations related to flexible perovskite solar PV. Talks will be initiated on a potential perovskite module factory in Brabant and the exchange of relevant information.

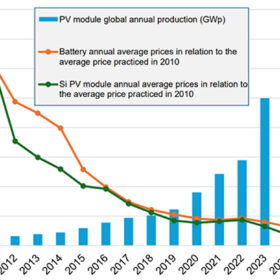

Falling Li-ion battery prices mirror solar photovoltaics trends: Is there a role for second-life batteries before recycling?

Lithium-ion batteries are everywhere, powering everything from consumer electronics to electric vehicles, residential PV storage systems, and, more recently, mitigating curtailment in large-scale wind and solar power plants. EVs are driving large-scale demand for Li-ion batteries which will result in substantial volumes of spent batteries in the near future. This scenario highlights the potential for repurposing EV batteries for second-life stationary applications, which could maximise their value before recycling. However, to fully realise this opportunity, several economic, technical, and regulatory challenges must be addressed and resolved.

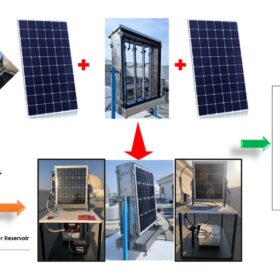

Cooling bifacial PV modules with mist

Scientists have placed mist nozzles inside a bifacial PV module and measured it under an extremely hot climate. The module was found to generate up to 37% more electricity on sunny days and up to 46% more on cloudy days compared to standard monofacial panels.

Beyond the hype: Why PERC still powers a stronger solar future

New doesn’t always mean better: Passivated emitter and rear contact solar cells have earned their place through real-world reliability and cost-effective manufacturability.

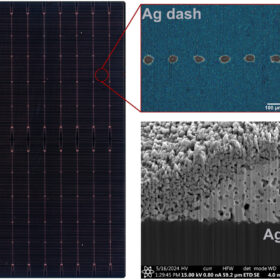

Silver-lean screen-printing can reduce silver use in TOPCon solar cells by 40%

An international research team has developed a metallization technique for TOPCon solar cells that can reportedly reduce silver usage in the devices’ rear side by 85%. The scientists replaced the commonly used Ag fingers with intermittent Ag dashes for contact formation and Ag-free fingers and busbars for electrical conduction.