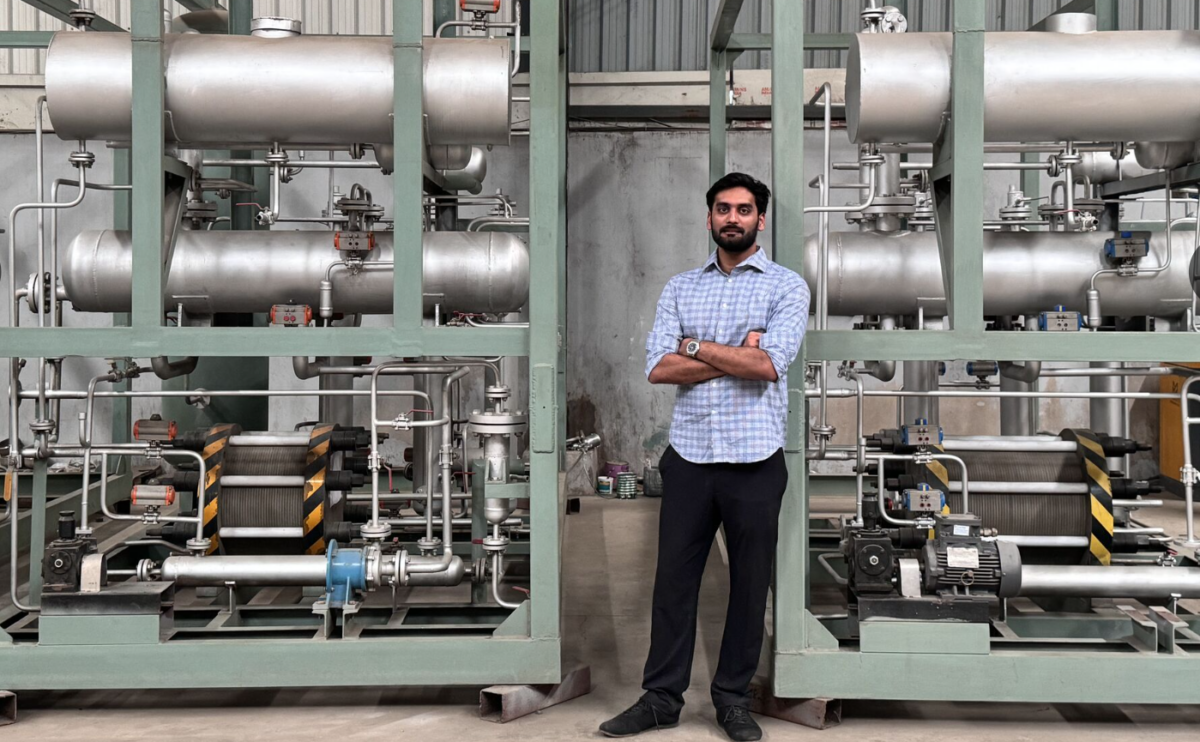

Airox Nigen Equipments, a turnkey solution provider for hydrogen production, storage and power, has announced the execution of more than 80 hydrogen generation plants across India, becoming the first company in the country to achieve this milestone.

Airox Nigen leverages its engineering and R&D capabilities to enhance hydrogen generation technologies and reduce the cost of green hydrogen production. The company targets to reach 100 hydrogen plants by 2025.

“The [existing] hydrogen generation plants, spread across various regions of the country, are equipped with cutting-edge electrolyzer technology, capable of producing high-purity hydrogen, which can be utilized in numerous industries such as oil refining, chemical production, transportation, and power generation,” stated Airox Nigen. “The company’s hydrogen generation plants are enablers of decarbonization in industries that have traditionally been dependent on fossil fuels.”

Airox Nigen has been present in green hydrogen technology since 1994, manufacturing in India without external collaborations. It has executed projects for companies like L&T, NPCIL, THDC and SJVN. In June this year, Airox Nigen Equipments announced the commissioning of its indigenously built alkaline electrolyzer and fuel cell for SJVN’s multi-purpose green hydrogen pilot project in Jhakri, Himachal Pradesh. It is also setting up a new electrolyser manufacturing facility of 3 GW scale at recently acquired 16 acres of land near Rohtak, Haryana.

Q Energy and Inthy have signed a joint development partnership for a hybrid renewable energy project in Burgundy, France. The two European companies expect to commission the green hydrogen production facility by 2028. “The project is designed to help decarbonize the fleets of local authorities, the region’s heavy goods vehicles and local industrial processes,” said Q Energy in an emailed note. The project spans 11 hectares and will feature a 5 MW electrolyzer and a 7 MW agrivoltaics plant on the same site.

Ørsted has told pv magazine that it has decided to step out of the H2RES project, leading to the dissolution of the hydrogen-focused consortium. The company said that the step out of Green Fuels for Denmark follows its decision to de-prioritize e-fuel efforts in Northern Europe, so the project is no longer aligned with its strategy. “We are aware that other partners in the project are exploring options for continuing Green Fuels for Denmark,” said the company in a note, adding that a sub-scale demonstration plant like this no longer has a relevance in the current market.

PureWave Hydrogen said it is exploring geological structures that could host naturally occurring hydrogen. The company uses proprietary software to analyze public datasets, AI systems to identify regions of interest, and advanced oil and gas exploration methods. Bruce Nurse, founder and director of the Colorado-based company, told pv magazine that its current work focuses on identifying features like four-way closures that may trap hydrogen, along with potential reservoirs. PureWave Hydrogen is concentrating on the Mid-Continent Rift in Kansas. It said it is also developing a strategic partnership with SnowFox Discovery and collaborating with geological consultants from academia and the oil and gas industry. “In terms of public support, we are actively exploring opportunities to leverage government programs and grants that focus on green energy innovation and hydrogen technology development,” said Nurse. “Moreover, we are considering accessing the public markets as part of our long-term growth strategy.”

ECap Marine has developed and installed a containerized system featuring two Ballard FCwave (2x200kW) fuel cells, a maritime battery system from Lehmann Marine, a fire extinguishing system, tank units, a custom power management system, and cooling and safety equipment. The Hamburg-based company said in an emailed note that it successfully ran the eCap Marine system on OSV Coastal Liberty for a number of months, and the vessel has now set sail on the Wadden Sea in Germany. Lars Ravens, managing director of eCap Marine, said the system is a unique installation for a seagoing ship and is scalable up to megawatt-sized designs for larger commercial ships and longer voyages.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.