Norwegian Ship Design Co. and Torghatten Nord have signed a shipyard contract to construct “the world’s two largest hydrogen ships.” The companies said that each ferry, spanning 117 meters, will accommodate 120 cars and 599 passengers, powered by 6,400 kW of fuel cells. “The ferries are designed for 100% zero-emission and feature a multi-hybrid propulsion system with hydrogen-electric as the primary mode and diesel-electric as the secondary mode,” added Norwegian Ship Design.

Provaris Energy and Norwegian Hydrogen have agreed to jointly identify and develop several sites in the Nordic region for the large-scale production and export of hydrogen to the European market. “New projects will be strategically located in areas with robust grid connections and power supplies,” said Provaris Energy. “These sites will facilitate the construction of state-of-the-art electrolyzers, and hydrogen compression facilities linked to export jetties. Provaris’ H2Neo carriers will transport the hydrogen, while the H2Leo barge will serve for storage.” The term of the agreement is 24 months.

The European Commission has drafted the terms and conditions for the second auction for renewable hydrogen production run by the European Hydrogen Bank. “The Innovation Fund will be launching a second auction before the end of 2024. As part of a “lessons learned” exercise, draft terms and conditions for the IF24 Auction are being published with the purpose of gathering structured feedback from the main stakeholders involved,” said the EU executive body. The document does not define the budget, but proposes reducing the ceiling price from €4.50 ($4.82)/kg to €3.50/kg. It also suggests increasing the value of the completion guarantee from 4% to 10% and reducing the time to enter into operation from five to three years. The first EU-wide auction closed in February, and evaluation results will be available in the coming weeks.

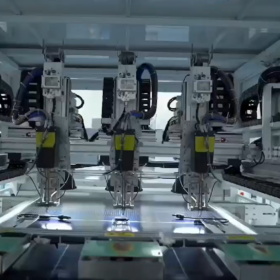

The Fraunhofer Institute for Machine Tools and Forming Technology (Fraunhofer IWU) has introduced a prototype system for roll embossing, which could lower costs and support the mass production of bipolar plates (BPPs). “The production line is up and running at Fraunhofer IWU. The system consists of three roll stands and requires an installation footprint of 4,500 mm x 3,300 mm,” said Fraunhofer IWU. Electrolyzers and fuel cells require bipolar plates, which consist of two conversion components: the membrane electrode assembly (MEA) in a fuel cell system and the catalyst-coated membrane (CCM) in an electrolyzer.

Stargate Hydrogen said it will launch its new alkaline electrolysis stack during the World Hydrogen Summit from May 13 to May 15 in Rotterdam. The Stellar 100 electrolysis stack is manufactured in Europe and has a green hydrogen production capacity of up to 100 Nm3/h. “We measured the average cell voltage in the stack to be lower than 1.85V (at 0.5 A/cm², 15 barg, 70°C), corresponding to a stack-level efficiency of 80% (HHV),” said Thomas Ottitsch, manager of the electrolysis test field (ElyLab) at the Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW).

Lhyfe and Ugitech have agreed to set up a green hydrogen production unit near Ugitech’s Ugine site in Savoie, France. Lhyfe plans to install a maximum of 30 MW of electrolysis capacity, producing up to 12 metric tons per day. “This green hydrogen would be used mainly at the Ugitech plant, supplied via a pipeline,” said Lhyfe. The companies are now entering the feasibility study phase of the project.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.