Su-vastika Systems, a Gurugram-based power and storage solutions provider, has filed for around 60 technology patents and has been awarded nine patents within four years of its inception. The company makes solar inverter and battery storage products and has been exporting 90% of its production.

“We target INR 100 crore exports this fiscal year. We have designed semi-automated/automated machines to enable production with minimal human intervention. These machines span various stages of production like wire cutting and core stacking for transformers,” Kunwer Sachdev, founder of Su-kam brand inverters and now a mentor for Su-vastika Systems, told pv magazine.

The latest from Su-vastika is an 80 kW lithium battery storage system, which it is pilot testing at its factory. The company has been using this battery storage system together with a 125 kVA diesel generator to run 110 kVA of electricity load at its factory. Whenever the battery goes low, the generator springs into action.

“This, however, is very rare,” Sachdev said. “Installing the system has helped us to reduce our monthly diesel bill to just INR 3,000 from INR 1.75 lakh.”

Image: Su-vastika

The battery of the system can also be charged through solar panels by adding a charge controller.

“We are designing storage such that you don’t need grid feed. Storage systems designed nowadays keep charging throughout the day via solar. On the other hand, our storage systems can start powering the systems as soon as their battery gets charged up to 25%.”

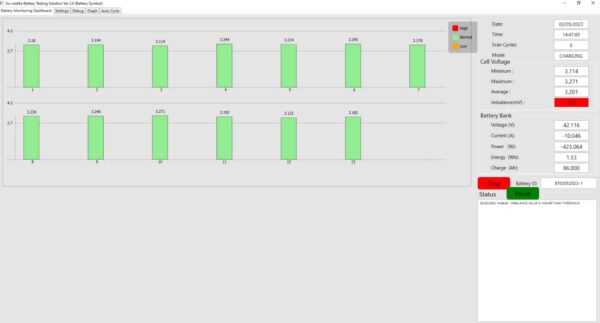

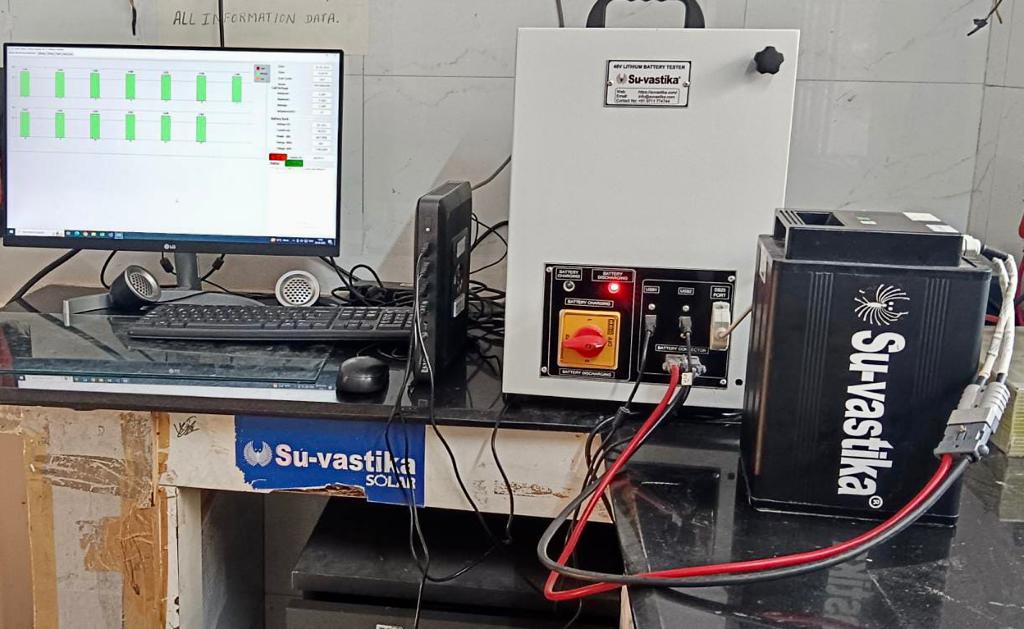

Su-vastika has also developed a lithium battery tester that it claims to be the first made-in-India product that can test a battery storage system at the cell level.

“The main reason for battery failure is the voltage imbalance across the cells in the battery bank. The lithium battery testing system developed by us can test the performance and reliability of each cell in the battery bank,” Sachdev told pv magazine.

Su-vastika

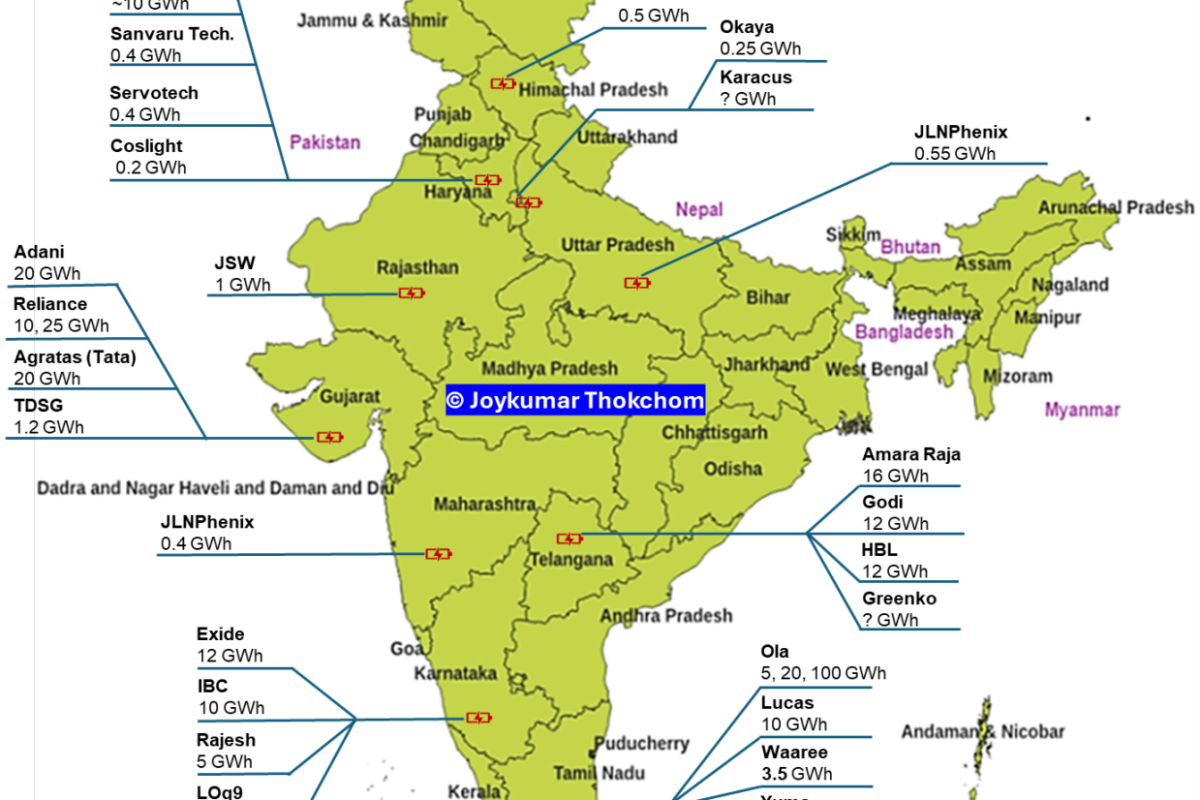

Su-vastika is banking on lithium ferro phosphate cells for its lithium battery products as these are much safer than NMC and other high-density chemistries.

“The main reason behind the recent incidences of electric scooter fire was the use of NMC batteries. OEMs used these batteries for their high density and small size. However, after the fire incidences, almost all have switched back to LFP chemistry.”

The company is planning big on lithium battery storage as these are much more reliable, safer, and space-efficient than conventional lead-acid batteries.

“Our focus is not just to introduce new products in this segment but also to convert the lead-acid batteries in existing inverters with lithium batteries,” said Sachdev.

“We can make any existing lead-battery inverter lithium battery compatible by adding a battery management system to it,” said Sachdev. “In fact, a normal inverter can also be made solar-compatible by adding a module called a charge controller.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Where are the Batteries, Inverters, Components coming from… China..???

Su-vastika Makes Quality Products

Very nice. All the best wishes for Su-Vastika .

Keep growing 💗