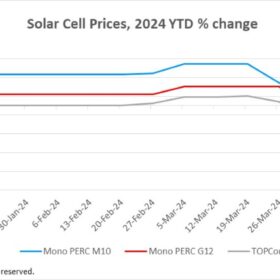

Accelerated declines in solar cell prices since late March

In a new weekly update for pv magazine, OPIS, a Dow Jones company, offers bite-sized analysis on solar PV module supply and price trends.

New metallization tech for HJT solar cells minimizes silver use, increases efficiency

German research institute Fraunhofer ISE has unveiled a new metallization process for heterojunction solar cells that reportedly increases power conversion efficiencies by over 0.1% while reducing silver consumption. A device built with the new technique achieved an efficiency of 23.2%.

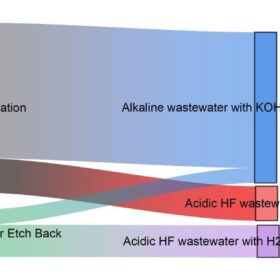

New water circulation tech promises lower PERC solar cell manufacturing costs

A German team developed models to illustrate water-saving potential in PERC silicon solar cell manufacturing based on a circular approach and commercially available technology. In the case of a 5 GW fab, water savings of up to 79% and wastewater discharge reductions up to 84% could be achieved, a “significant” improvement compared to a reference scenario.

Vikram Solar wins 250 MW module supply order from GIPCL

Vikram Solar will manufacture and supply bifacial PV modules for Gujarat Industries Power Co. Ltd’s project at the RE Park in Khavda village in Gujarat.

Solar bloodbath: Titans clash in ruthless price war

The ongoing price war between top global suppliers could catalyse more competitive solar panel pricing in the Indian market, potentially leading to an increase in solar adoption at both the commercial and residential levels.

Gstar working on 3 GW silicon wafer factory in Indonesia

Singapore-based Gstar Solar says it has broken ground on a new 3 GW silicon wafer factory in Indonesia, with production scheduled to start by the end of this year.

NTPC tenders EPC package for 260 MW solar in Rajasthan

NTPC Renewable Energy Ltd has invited domestic bids to develop a 260 MW grid-connected solar PV project in the Bikaner district of Rajasthan. Bidding closes on June 6.

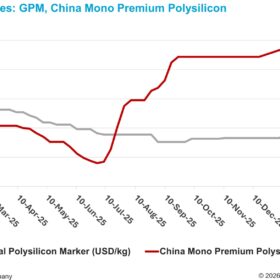

OCI increases production capacity at Malaysian polysilicon factory

OCI has revealed plans to invest $617.9 million to expand production at its Malaysian manufacturing facility from 35,000 to 56,600 metric tons.

ALMM expands market for domestic solar manufacturers

The ALMM reinstatement opens up a vast market for domestic solar panel manufacturers by creating a non-tariff barrier for Chinese products. However, for projects and schemes such as PM Surya Ghar: Muft Bijli Yojana which mandate domestic content requirement (DCR), the shortage of domestically manufactured cells could lead to an increase in the cost of DCR modules.

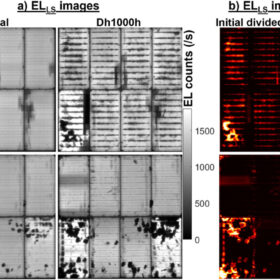

UNSW researchers warn of surprising TOPCon solar module vulnerabilities

Researchers at the University of New South Wales claim to have identified three TOPCon panel failure types that are absent in PERC products. They explained that these failures may occur when the modules are exposed to high humidity and contaminants before encapsulation.