Simplifying solar cell deposition

Scientists in Germany have developed a new process for deposition of silicon dioxide layers during cell production. Without the need for high pressure, flammable gases, or vacuum conditions, the process could lead to cost reductions for cell manufacturers, provided it can be developed and applied in a large-scale production setting.

Lithium saturation to make old batteries new

Scientists investigating the aging mechanisms affecting today’s lithium-ion batteries observed that the loss of lithium over time is one of the main causes of performance loss. With this in mind, they developed and tested a “relithiation” process that promises to eliminate much of the cost and complexity from recycling battery components and materials.

Nickel-salen for a battery that charges in 10 seconds

Scientists in Russia introduce a promising new material for battery energy storage, the product of more than three years of research. Incorporating a nickel-salen polymer into the cathode, the group demonstrated a battery that can charge and discharge ten times faster than today’s lithium-ion batteries. And though the battery still lags in terms of overall capacity, the group is confident that its discovery will lead to big improvements for lithium batteries.

The long read: Bifacial drives encapsulant switch

Suppliers of encapsulant materials – plastic sheets that are heated to laminate together the components in PV module stacks – are rapidly expanding to keep pace with module manufacturing in Asia and other parts of the world. Ethylene-vinyl acetate (EVA) continues to dominate the market, but new developments in module technology are driving a slow shift to more costly polyolefins.

An aluminum battery that can charge in a fraction of a second

Scientists in China and the United States investigated the inner workings of aluminum-ion batteries. With new insights into mechanisms at work within the battery during cycling, the group was able to demonstrate a battery capable of ultrafast charging, with the highest capacity so far reported for an aluminum battery.

Quantum dot solar cells and the search for stability

In various forms, quantum dot technology has attracted plenty of attention among PV researchers recently. And as efficiencies have crept past the 15% mark, the community is beginning to look at other factors limiting the viability of quantum dot solar cells in a commercial setting. Scientists in Germany examined the degradation mechanisms affecting different quantum dot materials; and suggest a standardization of stability testing to enable comparability of results.

Modeling the potential of lead-free perovskites

Scientists in India modeled the performance of tin-based perovskite (methylammonium tin triiodide) finding that with careful optimizations the material could achieve efficiencies beyond 28%.

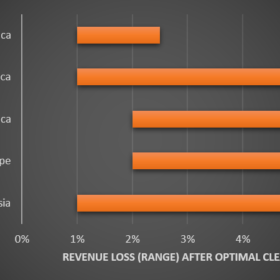

New model to predict PV module cleaning cycles and resulting profits

A group of scientists in Bangladesh has developed a model to determine the optimal cleaning schedule for a PV installation at any location in the globe, requiring only the average insolation and soiling rate for a given site to make the calculation. The study also draws new conclusions regarding the influence of sandstorms and rain on soiling, and aims to be among the first studies to paint a global picture of soiling trends by region.

The long read: Circular innovations

Slowly but surely, environmental concerns are making their way into mainstream thought throughout the PV industry. A look at recycling offers an example of this, with stakeholders trying to get ahead of the high volumes of end-of-life modules already on the horizon. pv magazine examines the technologies that will be needed, alongside policy and economic support, to keep the bulk of these modules out of landfill and ultimately to establish a circular economy for PV materials.

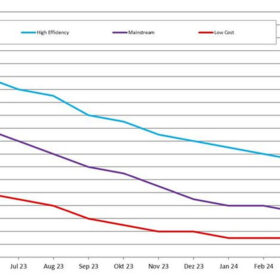

The long read: Made in MENA

Despite big ambitions and even bigger projects being built across the region, PV manufacturing in the Middle East has never got off the ground. In Saudi Arabia, however, one manufacturer is realizing plans for a gigawatt-scale module factory. Over the next five years, Desert Technologies plans to bring 3 GW of heterojunction production to the Kingdom. pv magazine takes a look at the challenges facing PV manufacturers in Saudi Arabia, and the opportunities the nation may hold.