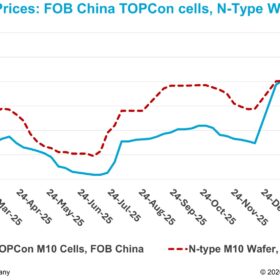

Trina Solar achieves 24.24% efficiency for 210 mm n-type TOPCon solar cell

Trina Solar said Germany’s TÜV Nord has confirmed the efficiency rating of its latest solar cell.

New battery for residential, commercial applications

Dutch manufacturer MG Energy Systems is offering a new storage system in two versions, with capacities of 5.8 kWh and 7.2 kWh and nominal capacities of 230 Ah and 280 Ah.

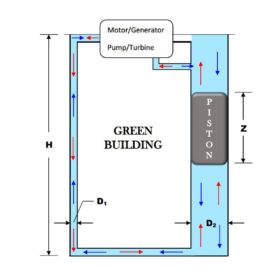

PV with gravity storage, redox flow batteries in buildings

Indian researchers have developed a new hybrid system featuring a conventional rooftop PV system, a solar tree, two gravity power modules for building (GPMBs), and a vanadium redox flow battery (VRFB), with power exclusively provided by the two solar installations.

Bhutan issues tender for 17.3 MW solar park

Bhutan aims to facilitate the construction of its first PV project through a new tender.

World’s largest underground hydrogen storage project

Mitsubishi Power Americas and Magnum Development are set to begin construction on a 300 GWh underground storage facility in the US state of Utah. It will consist of two caverns with capacities of 150 GWh, to store hydrogen generated by an adjacent 840 MW hydrogen-capable gas turbine combined cycle power plant.

Photovoltaic micro-inverter based on gallium nitride transistors

Scientists from France’s CEA-Ines developed a 400 W micro-inverter with a power density of 1.1 kW/L and an efficiency of 97%. The device utilizes GaN 600V diodes and power transistors developed by CEA’s electronic branch CEA-Leti.

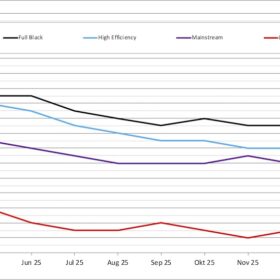

Using p-type wafers in heterojunction solar cells, not a lost battle

An international research group has reconstructed the trajectory of p-type wafers in the heterojunction solar cell segment and has identified the lack of knowledge about boron-oxygen related light-induced degradation (BO-LID) as the main cause for the limited adoption of these wafers and the success of their n-type counterparts. According to the scientists, however, there is still big room for improvement for p-type technologies in heterojunction cells.

The PV industry needs 12 times more polysilicon production capacity by 2050

New research from the University of New South Wales (UNSW) predicts cumulative polysilicon demand of 46-87 Mt will be required to achieve 63.4 TW of PV installed by 2050.

Cooling down solar modules with cotton wicks immersed in water

The novel technique consists of attaching cotton wicks immersed in the water (CWIWs) to the backside photovoltaic module. The water is supplied to cotton wicks from top to bottom by gravity which the scientists said helps the effective absorption of cotton and reduces water consumption.

Portable flexible PV systems for off-grid, residential applications

US startup New Use Energy Solutions has launched a new line of portable PV systems built with a module technology relying on Merlin Solar’s panels. The modules are assembled in the system via a custom vinyl tarp.