From pv magazine Global

Researchers from the King Abdullah University of Science and Technology (KAUST) in Saudi Arabia have developed a solar-powered integrated water-electricity-crop production system that is able to produce water from atmospheric water vapor.

“Our system is suitable especially for off-grid communities anywhere as it provides an easy way of getting electricity, water, and crop products for point-of-consumption,” the research’s corresponding author, Peng Wang, told pv magazine.

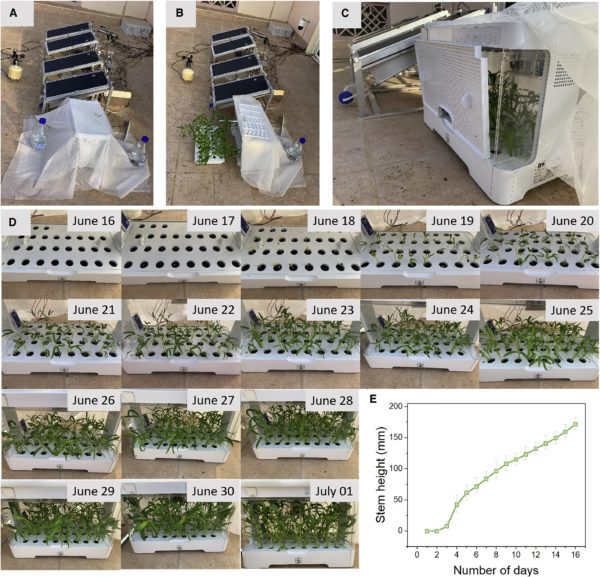

Called WEC2P, the system relies on a PV system to generate power and an atmospheric-water-harvesting (AWH) material to produce water vapor from the air. The freshwater produced by the AWH device is used either to grow crops or to reduce the operating temperature of the solar modules. The system works in two operation modes, which the scientists called AWH-PV cooling mode and AWH-water and crop production mode.

The cooling device consists of a polyethylene (PE) anti-corrosion film with a thickness of around 0.04 mm, polymer-based atmospheric water-vapor sorbents, and a polyacrylamide-calcium chloride (PAM-CaCl2) hydrogel. “The as-obtained PAM-CaCl2 hydrogel was directly attached to the backside of each individual PV cell in the PV panels via its self-adhesion properties,” the Saudi group explained. “A poly (methyl methacrylate) (PMMA) plate-shaped frame was installed by spring bolts to reinforce the adhesion of PAM-CaCl2 hydrogel with PV panel and secure their close contact.”

The excess heat extracted during the cooling operations is used to drive the water to evaporate from the polymer-based sorbents during the daytime. This evaporated water vapor is then collected during the daytime in a condensation chamber that is utilized as a passive condenser.

Image: KAUST

The surface area of the condensation chamber, which is made of an aluminum alloy with a copper nozzle at the lower sidewall is 1.6 times, that of the overlying four south-oriented PV panels, which were deployed at a tilt angle of 22 degrees. A cotton wick passing through the nozzle was used to help the extraction of the condensed water into a water-collection bottle. “Each PV panel was considered as an independent module and was connected with an MPPT system and a 12-V lead-acid battery,” the scientists emphasized. “Furthermore, each module was connected with a total of 20-W light-emitting diode (LED) light strips as a load to discharge the battery at night when the PV panel was not in operation.”

The performance of this system design, both with and without the cooling system, was analyzed at an outdoor testing facility aimed at growing spinaches located in Thuwal, Saudi Arabia, over a 3-month period during last summer.

The proposed system configuration was found to allow a 9.9% increase in power generation thanks to a reduction of the operating solar module temperature by up to 17 degrees Celsius. The small spinach growth unit registered a crop surviving rate of 95%.

The costs of the systems haven’t been estimated so far by the researchers. “The performance is far from being optimized and thus it would be not possible to reasonably estimate the overall cost of the system when scaled up,” Wang affirmed.

The system was introduced in the paper An integrated solar-driven system produces electricity with fresh water and crops in arid regions, published in Cell Reports Physical Science.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.