From pv magazine Global

Researchers at Germany’s Fraunhofer Institute for Solar Energy Systems ISE have been seeking for several years to reduce silver usage — a main concern for the PV industry — in the metallization of TOPCon solar cells, for which relying on lower amounts of the precious metal is crucial to reduce manufacturing costs and gain further market share.

Recently, a group of scientists from the German institute used contacts based on galvanic nickel (Ni) copper (Cu) and silver (Ag) instead of common silver contacts to fabricate an n-type bifacial TOPCon cell that is claimed to achieve higher efficiency than its counterparts with printed silver contacts, while also reducing silver consumption by 90%. “Even in industrial production, this galvanic metallization enables significant silver savings without having to compromise on efficiency,” said researcher Sven Kluska.

Designed for screen-printed metallization, the cell was fabricated with an industrial-type boron emitter on the textured front side passivated by a stack made of aluminium oxide and silicon nitride (AlOx/SiNx). The rear side was made with a TOPCon layer with a tunnelling oxide and a highly n-type doped poly-Si layer which is covered by a SiNx layer.

“The plating process combines two single side electroplating steps of a Ni/Cu/Ag stack subsequently on each side,” the scientists said referring to the metallization technique used. “The Ni and Cu were supplied by Atotech Group, whereas the Ag electrolyte is identical as presented by Grübel.”

The rear TOPCon side is initially plated by performing a hydrofluoric acid (HF) pretreatment process intended to remove native and laser-induced oxide layers within the laser contact opening (LCO). In a second step, a Ni-Cu stack is deposited by light-induced plating (LIP) and finished by an Ag immersion plated capping.

The performance of the plated cell, which has a full area of 268 cm2, was compared to that of a similar device that went through screen-printed metallization. The champion plated device achieved a power conversion efficiency of 23.84%, an open-circuit voltage of 709 mV, a short-circuit current of 40.9 mA cm−2, and a fill factor of 82.2%. The screen-printed cell showed an efficiency of 23.46%, an open-circuit voltage of 708 mV, a short-circuit current of 40.4 mA cm−2, and a fill factor of 82.0%

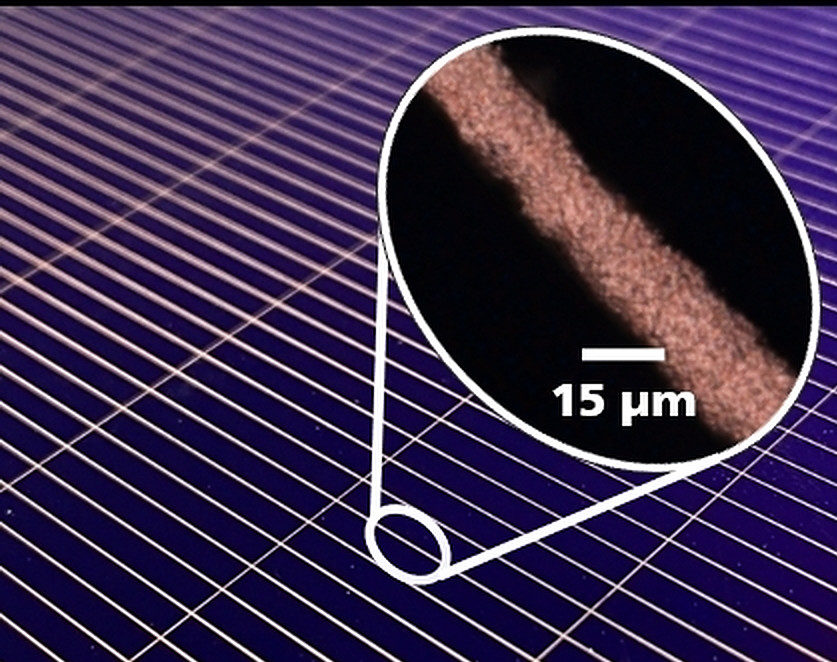

Reducing the LCO width and adapting the number of fingers, the plated contacts benefit from narrower contact widths down to 5.5 μm, allowing a short-circuit current gain of nearly up to 0.5 mA/cm2, the academics explained. “There were no indications of the LCO width impacting the contact adhesion. Optimization of the HF pretreatment prior to the plating process showed an improvement of the contact resistivity allowing to stabilize the fill factor above 82% despite smaller contact geometries than the screen-printed references.”

The cell and the related manufacturing process are described in the paper Progress of plated metallization for industrial bifacial TOPCon silicon solar cells, published in Progress in Photovoltaics. “Plating metallization reveals to be a suitable candidate to metallize i-TOPCon solar cells with high efficiencies exceeding the screen-printed baseline metallization,” the scientists concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.