From ESS News

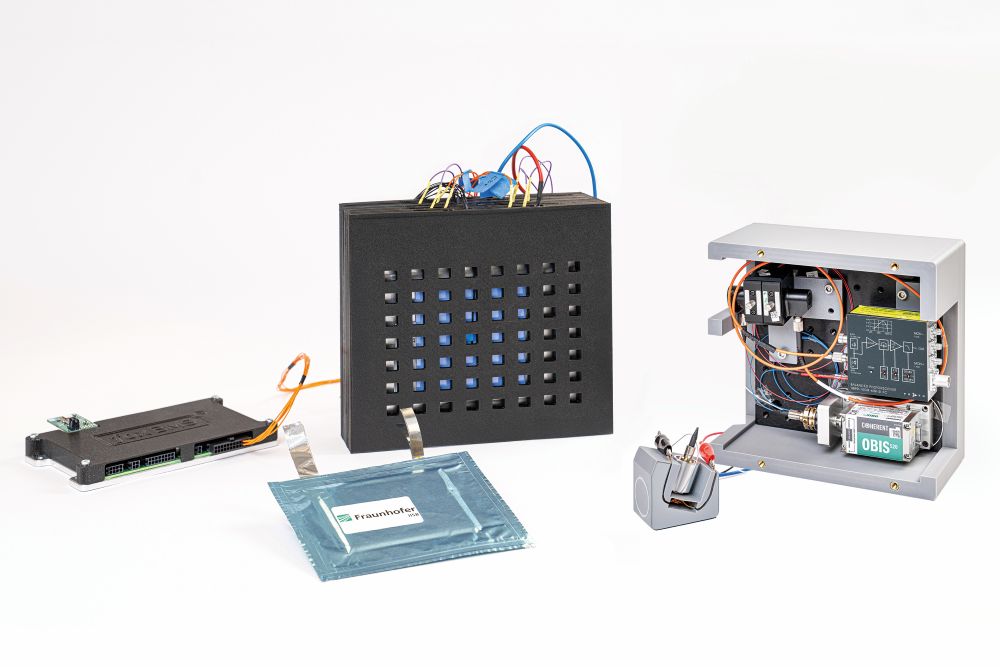

In a milestone for lithium-free battery technology, the collaborative R&D project INNOBATT, led by the Fraunhofer Institute for Integrated Systems and Device Technology (IISB), has completed a battery system demonstrator based on aluminum-graphite-dual-ion batteries (AGDIB). The demonstrator confirms the stability of this new cell chemistry not only in laboratory conditions but also under realistic operational scenarios.

The rechargeable aluminum-ion battery is a cost-effective, non-flammable energy storage technology that uses easily obtainable active materials – aluminum and graphite. With natural graphite as the cathode material, AGDIB cells can achieve energy densities of 160 Wh/kg and power densities exceeding 9 kW/kg. As a high-power storage device, the aluminium ion batteries can be charged and discharged rapidly at high C-rates, enabling fast-response applications.

According to Fraunhofer IISB, the reversible chemistry allows over 10,000 cycles at 100 % depth of discharge (DoD) in laboratory test cells, with nearly 100 % Coulombic efficiency and energy efficiency above 85 %. The corrosion-resistant multi-layer pouch cells developed for aluminium ion batteries have capacities of up to 200 mAh, achieving more than 1,000 cycles for 4-layer 200 mAh cells at 6 C and over 7,000 cycles for single-layer 30 mAh cells at 30 C.

With such capabilities, aluminium-ion batteries show great potential for stationary and hybrid mobile applications, particularly as USP systems and high-performance storage devices for dynamic grid stabilization, where frequent low-energy micro-cycles demand high power rather than high energy density.

While many new lithium-free battery technologies remain at the lab scale, system-level demonstrators are rare. Within the INNOBATT project, a full battery system demonstrator has now been established after prior scaling of AGDIB technology to small-size pouch cells, Fraunhofer IISB reported in late November. Development focused on the entire value chain: sustainable lithium-free cell chemistry, integration of a wireless battery management system (BMS), bidirectional quantum-based current sensing, and recyclability.

To continue reading, please visit our ESS News website.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.