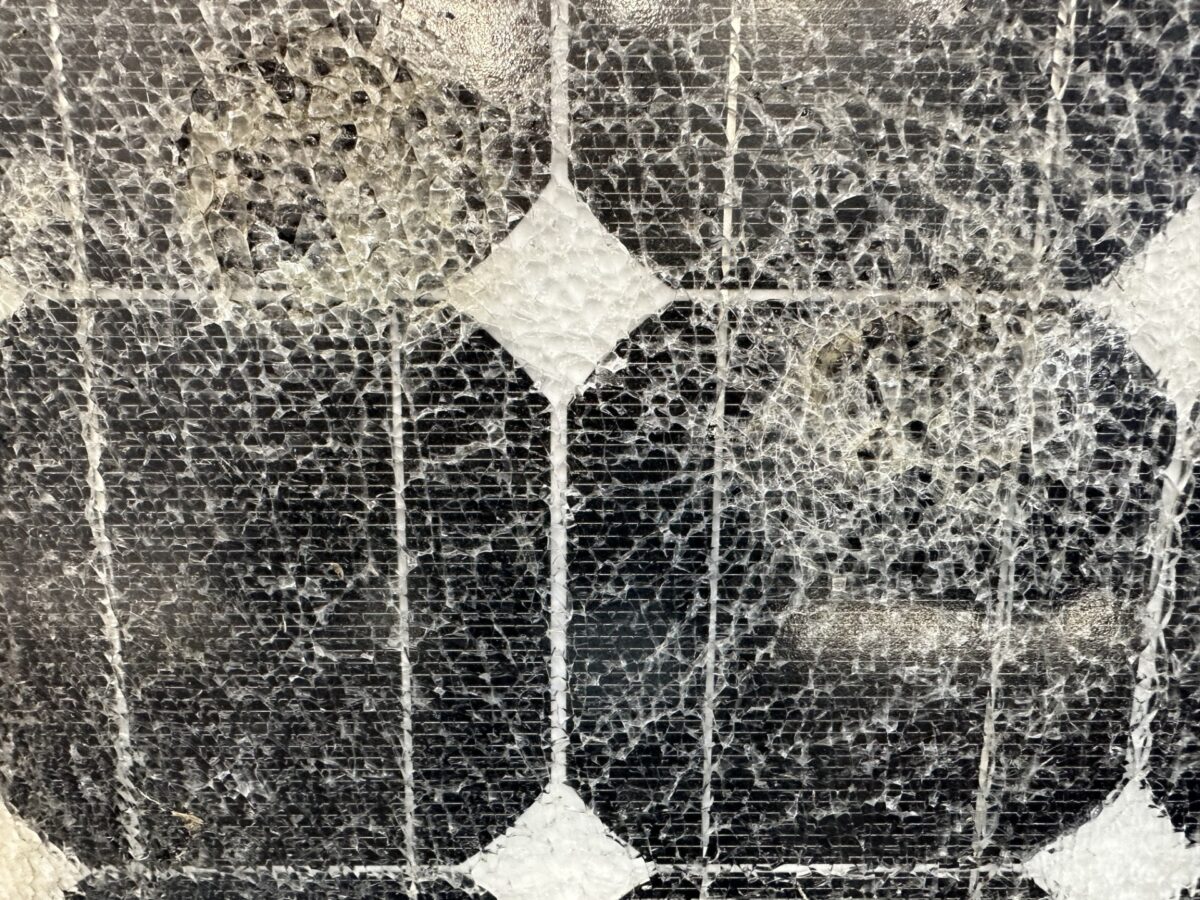

A team of researchers at Nanyang Technological University in Singapore has developed a process to use solar panel glass waste as a raw material for cathodes in solid-state lithium metal batteries.

By milling broken solar glass waste into nano-sized particles, they could process it for use as a functional inorganic filler in polyethylene oxide-based (PEO) solid polymer electrolyte (SPE) material. The resulting SPE demonstrated improved electrochemical stability and ionic conductivity.

Batteries made with the SPE containing 2 wt% glass nanoparticles retained a capacity of 123.07 mAh g⁻¹, indicating an 8.3% improvement over the reference.

To make the recycling of end-of-life (EoL) solar panels more attractive financially and sustainable, researchers have been investigating upcycling, processing waste panel materials into high-value products, while trying to avoid high-temperature processes.

In one of the latest instances, Nanyang Technological University researchers in Singapore proposed reusing glass in energy storage applications, noting that it is the heaviest EoL panel component and that valuable upcycling applications are lacking.

“Our research demonstrates that waste solar glass from end-of-life (EoL) solar panels holds promising potential in the energy storage sector, particularly as a functional additive in solid polymer electrolytes (SPEs),” corresponding author, Yeow Boon Tay, told pv magazine, adding that conventional recycling methods for solar glass are often energy-intensive and economically unviable.

“By directly repurposing or upcycling solar glass into functional nanomaterials, this work promotes a more sustainable and circular approach, linking two rapidly growing industries—solar energy and energy storage,” said Boon Tay.

The research, which is detailed in “Re-using end-of-life solar waste for solid state lithium metal batteries,” published in Resources, Conservation and Recycling, describes the use of solar glass nanoparticles as inert, cost-effective, and sustainable filler SPE for use in sample lithium iron phosphate (LFP) cathodes

SPE technology is seen as a “critical enabler” for next-generation solid-state batteries due to its enhanced safety and performance, according to Boon Tay.

“To isolate the solar glass from the PV, Solvent soaking and wire slicing were used to isolate the glass, avoiding energy-intensive thermal methods typically used to remove the ethylene vinyl acetate (EVA) encapsulant,” said the team. It then used a ball milling process to mill the broken glass without the use of toxic chemicals to approximately 300 nm. These nanoparticles were then incorporated as a filler into a polyethylene oxide-based (PEO), a commonly used SPE, according to the research.

“Our approach uses a simple and direct physical method to convert waste solar glass into nanoparticles, avoiding chemical-intensive synthesis routes. This makes the process significantly more cost-effective and less energy-intensive compared to traditional methods of producing inert fillers. Additionally, by utilizing recycled glass as the raw material, the overall carbon footprint is substantially reduced, enhancing its sustainability profile,” said Boon Tay.

The group found that the glass-modified SPE demonstrated an increased electrochemical stability and an improved ionic conductivity. “Specifically, the ionic conductivity of pure PEO with LiTFSI (lithium salt) SPE, measured at 9.66 × 10⁻⁶ S/cm at room temperature, increased to 1.10 × 10⁻⁵ S/cm upon the addition of 2 wt % glass nanoparticles,” it stated.

Lithium metal batteries were made with the resulting SPE and evaluated for performance by the researchers. The results demonstrated superior cycling stability for SPEs containing glass nanoparticles. After 80 cycles, the specific capacity of the reference dropped to 113.60 mAh g⁻¹, while the sample containing 2 wt % glass nanoparticles retained a capacity of 123.07 mAh g⁻¹, indicating an 8.3% improvement.

“These findings emphasize the potential of repurposing glass waste from solar panels into functional nanomaterials for SPE applications,” they concluded.

Asked about what is next for the research team, Boon Tay stated that developing low-impact methods to recover and repurpose high-quality materials from end-of-life solar panels is the focus, particularly energy storage applications. “Beyond this study, we’ve also developed low-temperature processes to upcycle recovered silicon into lithium-ion battery anodes, supporting a more circular and sustainable renewable energy ecosystem,” said Boon Tay.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.