From pv magazine Global

Japanese investment holding company Softbank is developing a wide range of technologies for its planned ultra-lightweight high altitude platform station (HAPS), a solar-powered aircraft meant to operate at an altitude of 20 km above the earth’s surface carrying telecommunications base stations as the payload.

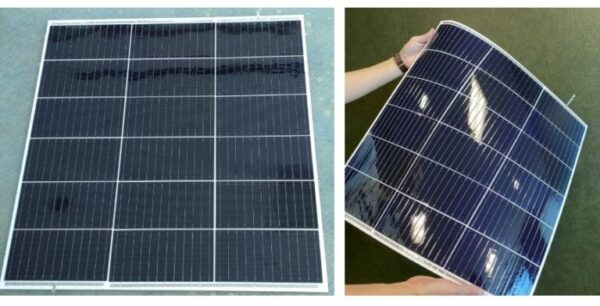

One of its research projects completed in March this year targeted a silicon PV panel of less than 700 g/m2, inspired by the high-efficiency silicon PV modules used in solar car racing. It was described in an R&D article, “The Challenge of Ultra-Lightweight Solar Modules for HAPS,” published on Softbank’s website.

In the paper, the team explained why they were pursuing silicon PV technology, “The lightest and most efficient solar cell currently available is the compound solar cell for space applications, but it is expensive and takes a long time to manufacture,” it stated. “For this reason, we selected the high-efficiency crystalline silicon cells, which are available at about 1/1000 the price.”

The project, which had participation by Japan-based Fujipream Corporation and Chinese module maker Longi, achieved a silicon heterojunction 665g/m2 panel, even lighter than the project’s target of 700 g/m2.

Made with cell technology from Longi, the same 80 µm HJT technology used to build a record-breaking cell unveiled in 2022, the encapsulated modules measured 563 mm x 584 mm and weighed 218.5 g. The maximum output power of 71.1 W was measured under the standard spectra AM 1.5 for a module efficiency of 22.2% on the effective area.

To reach the target weights, all the materials were much thinner than conventional panels. The front cover, the cells, encapsulants and backsheet measured 25 µm, 80 µm, 150 µm, and 50 µm, respectively.

The connections at this size were a challenge. “Thin copper wire with a diameter of 250 µm was selected for the cell-to-cell direct connections, which were connected using low-melting-point solder,” said the researchers, noting how it used a manual process.

Further research is planned towards a 500 g/㎡ target. “In order to achieve this goal, we will continue to develop modules with the aim of making each component of the module even thinner and higher performance, as well as improving wiring and laminating technology,” said the researchers

Indeed, the Softbank spokesperson confirmed to pv magazine that a new project is underway. “Solar module manufacturer Fujipream Corporation is our partner for this research project,” they said, adding that it is not limiting itself to a particular solar cell manufacturer for the work.

Softbank has been working with external partners from industry and academia since 2017 towards solving the technology challenges on the way to reaching its HAPS goals. For example, it announced this month a successful second field trial of its Sunglider HAPS aircraft with U.S. aerospace and defence technology company AeroVironment in the U.S. state of New Mexico.

Image: Softbank

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.