Researchers at Durham University have examined the viability of different hybrid renewable energy system (HRES) configurations to meet the electricity demand of the Netsi village community in the Jaisalmer district of Rajasthan and use the excess electricity generation for green hydrogen production.

The total electricity demand of the Netsi village is 1,026.5 kWh/day, including the power requirements for a primary school, 250 houses, a primary health center, a business center, and streetlights.

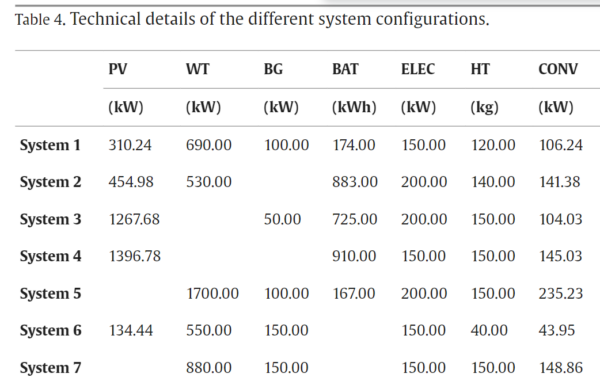

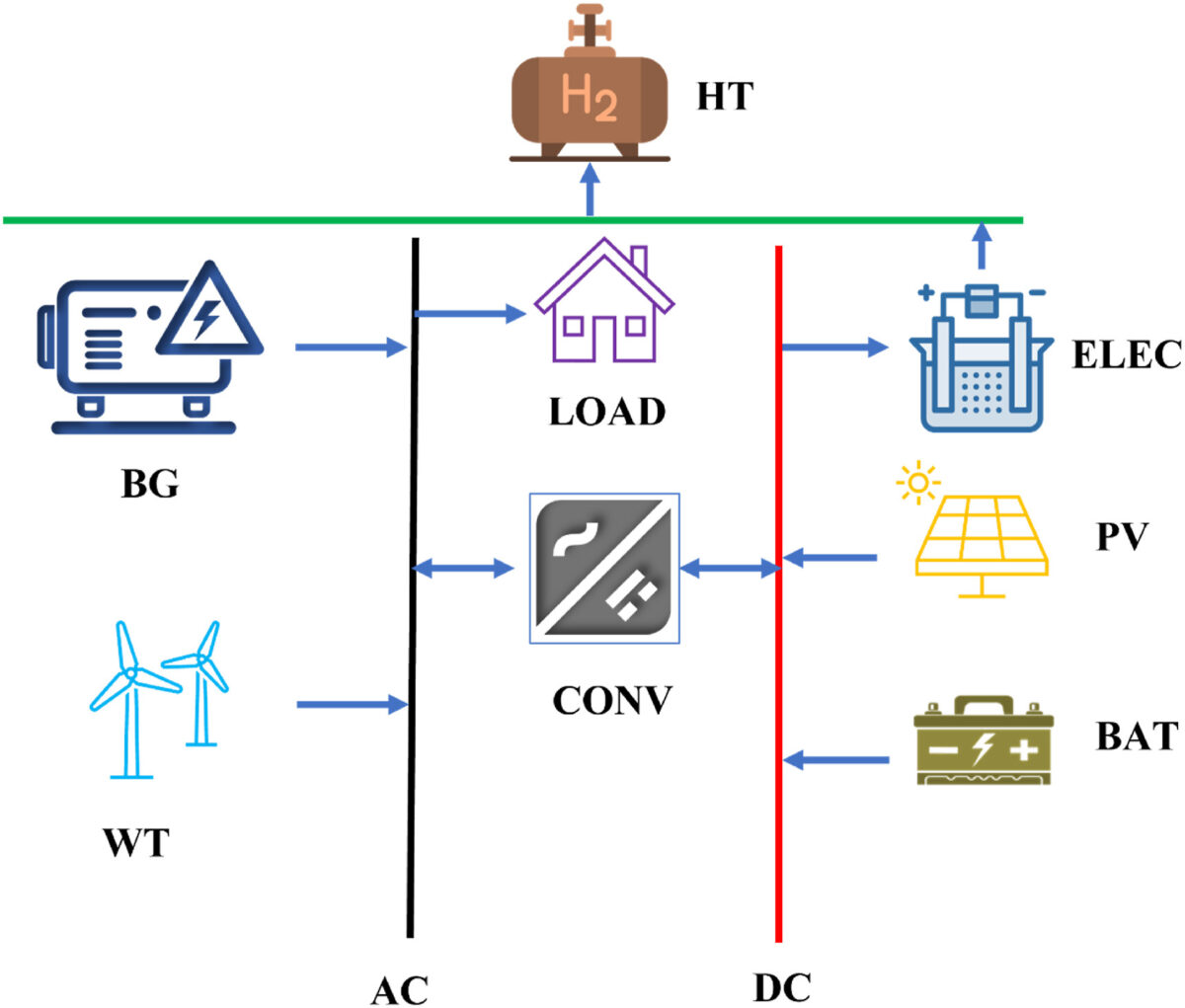

The researchers evaluated seven HRES configurations comprising different combinations of components, including photovoltaic panels, wind turbines, biogas generators, lithium-ion batteries, converters, electrolysers, and hydrogen tanks. The excess energy generated by the systems is stored in the batteries or used to produce hydrogen through the electrolysers. PEM electrolyser produces green hydrogen by consuming excess electricity generated by the system.

Systems were modelled using MATLAB software, and the HRES configurations sized by minimising the levelised cost of energy.

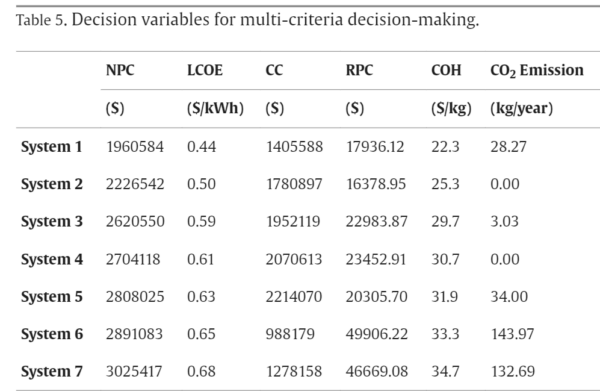

[Solar data and wind velocity information for the Netsi village site was obtained from NASA databases. At Netsi village, the monthly solar radiation varies between 3.44 kWh/m2/day to 6.59 kWh/m2/day, with an estimated average of 5.13 kWh/m2/day throughout the year. The solar radiation data considered for the analysis represents an average over a 22-year period, spanning from July 1983 to June 2005.]To identify the best performing HRES configuration, the systems were analyzed for economic and environmental performance parameters by applying the multi-criteria decision-making method TOPSIS. Furthermore, a detailed technical, economic, and environmental analysis was performed on the optimal HRES configuration.

The systems were analysed for their net present cost, LCOE, capital cost (CC), replacement cost (RPC), cost of hydrogen (COH), and CO2 emission.

The study finds that a HRES comprising PV system with a size of 310.24 kW, wind turbine 690 kW, biogas generator 100 kW, battery 174 kWh, electrolyzer 150 kW, hydrogen tank 120 kg, and converter 106.24 kW is the best-performing among all the evaluated systems since it provides the highest relative closeness (RC) value of 0.817 and also has the lowest fuel consumption rate of 2.31 kg/kWh. The minimum net present cost, levelised cost of energy (LCOE), and cost of hydrogen for this system are estimated to be $1,960,584, $0.44/kWh, and $22.3/kg, respectively.

The research findings are published in the Elsevier Journal of Cleaner Production Volume 443.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.