As India, US and Europe pave the way for localized manufacturing of advanced technologies and materials, it’s imperative to understand the complex value chains & ecosystem related to these emerging sectors.

The global transition towards renewable energy sources underscores a monumental shift towards sustainability and environmental stewardship. Industries such as solar, green hydrogen, and lithium-ion spearhead this movement, offering promising avenues for a cleaner, greener future. However, amidst the promise of progress, manufacturers in these sectors encounter a plethora of challenges that threaten to impede their journey.

One of the foremost challenges lies in setting up new manufacturing plants is the overly-dependence on China as primary supplier of raw materials and advanced equipment for their processes. For manufacturers to go beyond this and explore technologies available across the globe needs a deep understanding of the global supply chain.

Also, the “Make in India” initiatives for these emerging technologies require the development of an entire ecosystem within the country to establish true self-reliance. This means the manufacturing companies need to have access to information about latest technologies, the suppliers and also get a sound understanding of the applications of their products.

Digital ecosystems

Overcoming industry challenges requires collective efforts and partnerships that foster innovation and shared growth. This is why digital ecosystems are now becoming the buzz words and a necessity for the manufacturing companies in the renewable energy value chains like solar, green hydrogen and sustainable energy solutions like lithium-ion batteries.

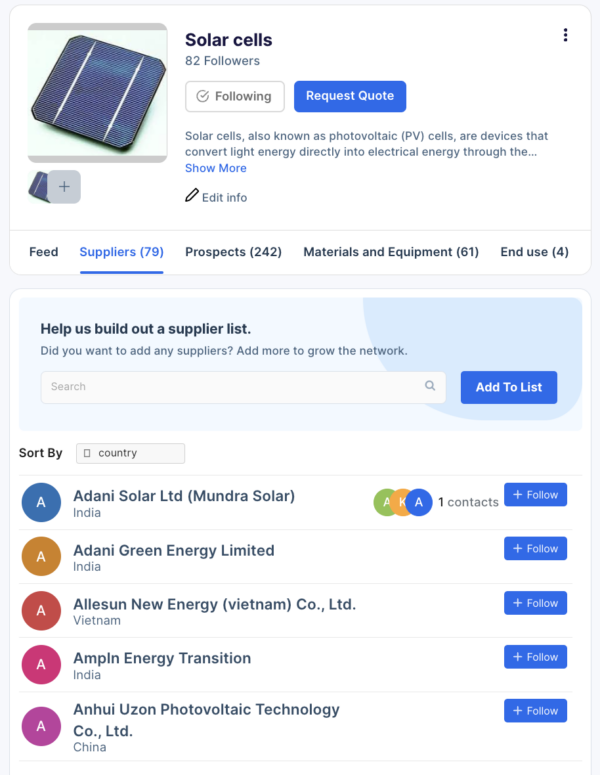

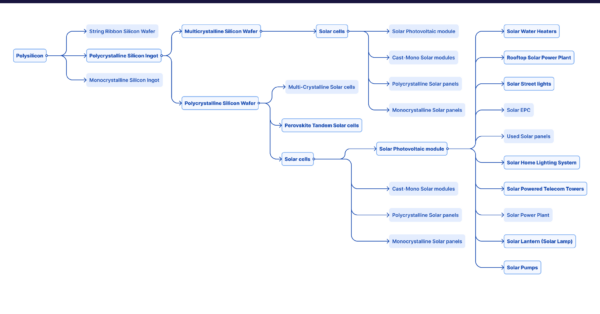

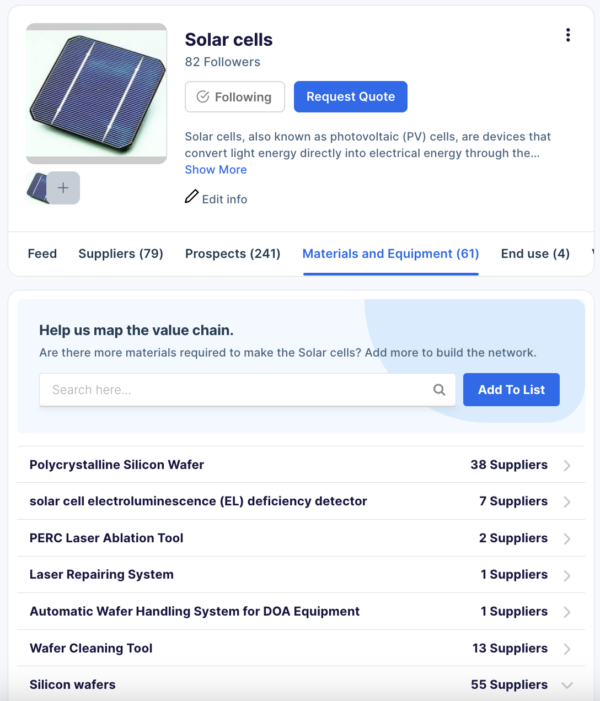

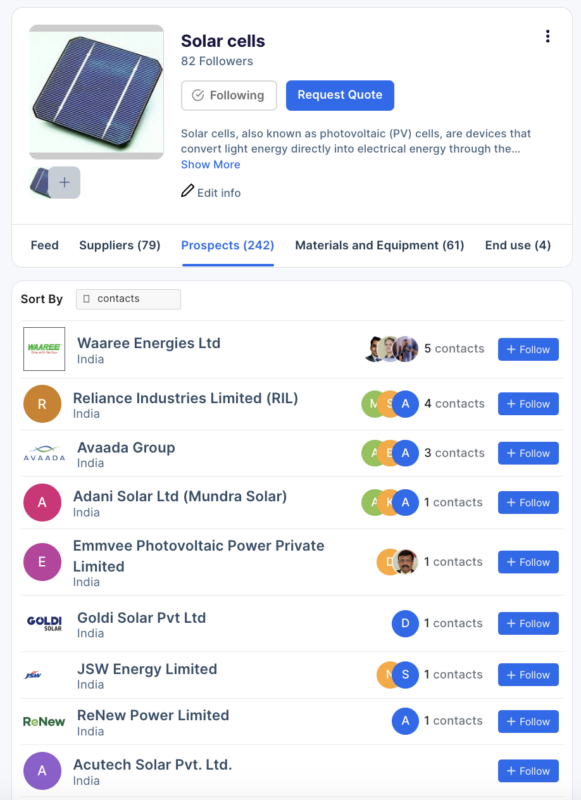

Digital ecosystems provide a centralized hub where manufacturers seamlessly connect with global suppliers, streamlining procurement processes and empowering the establishment of new plants with efficiency and ease. This gives manufacturers an in-depth understanding of the value chain that eventually simplifies their sourcing and supply chain management processes.

Mapping the complete digital value chain

While government incentives may spur production in certain segments, manufacturers often rely heavily on imports for critical equipment and materials.

Achieving true self-reliance in manufacturing demands a comprehensive understanding of the entire value chain. A solar cell manufacturer needs to understand who is making the silicon wafers for them, or a green hydrogen electrolyser company must have a sound knowledge of the technologies needed for their production process. All this can happen only through meticulously mapping of the complete value chain from raw materials to finished products. This enables manufacturers to localize production and reduce dependence on imports.

Unlocking new markets and opportunities

Expanding into new markets poses a significant challenge for manufacturers, particularly in growing economies like India. The absence of a centralized platform for communication and collaboration stifles growth potential and inhibits innovation. The B2B digital ecosystems also provide a platform for the manufacturers to showcase their products and connect with customers worldwide, that facilitates the discovery of new business opportunities and accelerates growth in emerging markets.

Fostering collaboration and innovation

Information silos often cripple innovations. Since these are fairly new and highly dynamic verticals, manufacturers struggle to discover novel technologies relevant to them and establish strategic partnerships. A collaborative ecosystem fosters knowledge sharing and connects industry professionals to accelerate the pace of technological advancement in these verticals.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.