Organic photovoltaics (OPV) have been proposed as suitable for wearable electronics that are attached to clothing to monitor medical devices without requiring battery changes. This latest research opens possibilities that solar cells could be put onto clothes and still function correctly after being rained on or even washed.

With this in mind, researchers led by Japan’s RIKEN Center for Emergent Matter Science (CEMS) developed an organic photovoltaic (OPV) cell that uses a hole transport layer based on silver oxide (AgOx). The novel HTL is designed to ensure waterproofness even under mechanical deformation, as it reportedly increases the adhesion between the electrode and active layer interface

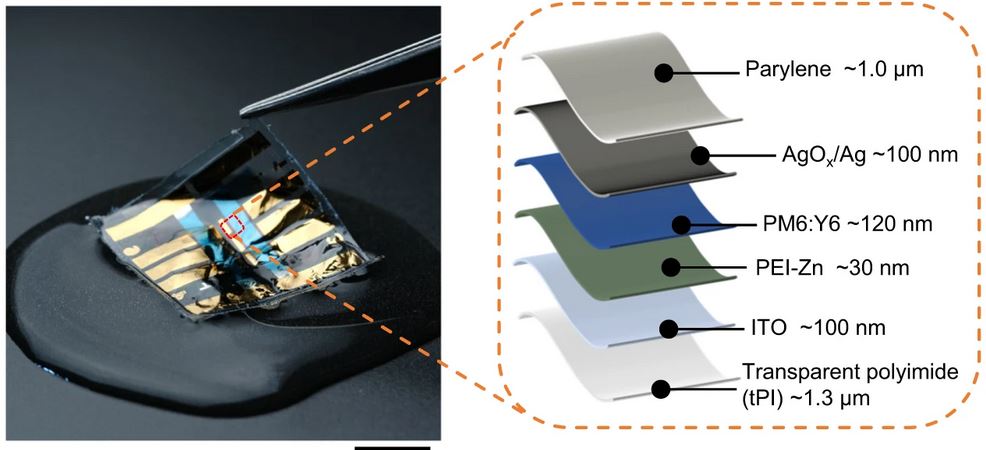

In the research paper “Waterproof and ultraflexible organic photovoltaics with improved interface adhesion,” published in nature communications, the scientists explained that they grew the AgOx HTL in situ with a structure of transparent polyimide. They deposited the anode layer, a silver electrode, directly onto the active layers, creating better adhesion between the layers. They used a thermal annealing process, exposing the film to air at 85 C for 24 hours.

“It was challenging to form the layer, but we were happy to have accomplished it, and in the end were able to create a film that was just 3 micrometers thick,” said Sixing Xiong, the paper’s first author.

When the film was immersed completely in water for four hours, researchers found it still had 89% of its initial performance. According to the research paper, waterproofness was tested at 0 C, 20 C, and 40 C and results indicated waterproof performance remains largely unaffected by temperature.

When the film was subjected to stretching by 30% underwater 300 times, it retained 96% of its performance. The paper says the result “emphasizes that OPVs with AgOx/Ag electrodes maintain stability even when subjected to mechanical deformation underwater, highlighting their suitability for wearable electronics.

The film also survived being run through a washing machine cycle, something the research paper says has never been reported before.

“OPVs with AgOx/Ag electrodes remained 90% of their original PCE (power conversion efficiency) after two washing cycles in a washing machine,” the paper says. “Furthermore, these findings suggest that OPVs with AgOx/Ag electrode can maintain continuous operation underwater, thereby enabling long-running power source for underwater autonomous systems and sensors.”

“What we have created is a method that can be used more generally,” said Kenjiro Fukuda, a corresponding author of the paper. “Looking to the future, by improving the stability of devices in other areas, such as exposure to air, strong light, and mechanical stress, we plan to further develop our ultrathin organic solar cells so that they can be used for really practical wearable devices.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.