From pv magazine 02/2022

The next generation of PV inverters has long been promised to be powered by silicon carbide (SiC) semiconductors. The shift toward high-voltage SiC metal oxide semiconductor field effect transistors (MOSFETs) replacing silicon insulated-gate bipolar transistors (IGBTs) has been decades in the making. With significant advantages for multiple industries, volume production has finally seen rapid increase in recent years.

Two of the hottest industries are electric vehicles, where replacing silicon with SiC in power applications has led to a range boost, and solar, particularly in string inverters. The path to this point has been complicated, thanks to material difficulties, silicon dominance, and slow breakthroughs.

Peter Friedrichs, vice president SiC at Infineon, told pv magazine that work on SiC as a semiconductor material dates back to the earliest days of semiconductors. “It really goes back to the 1950s, where semiconductors in general were not yet well developed. Germanium and silicon were really used commercially simply due to the availability of base materials as an entry material, and that was the biggest obstacle for silicon carbide,” said Friedrichs.

“The concepts of silicon carbide were known for many, many years. For basically 30 years there was some limited R&D worldwide to develop a process to create usable material. This was successful around 1985-86, to finally grow usable carbide crystals which could then be used for devices.”

The next important moment came around 1990, when several international groups, including Friedrichs’, then still within Siemens, started to develop early devices based on SiC. By 2001, the first commercial devices were SiC schottky diodes for power supply applications.

Nevertheless, Dipanwita Dutta, a research and development engineer at Hitachi Energy India, noted that SiC was a particularly “difficult” material when compared with silicon.

“Oxidation of silicon carbide is super tricky. If there is a minute impurity, you create a lot of defects. Making a transistor, a three-terminal device, is incredibly tricky. All of the studies you will see are mostly on how to handle these defects, how to passivate these defects, and how to make a better transistor,” said Dutta.

“Really, no one believed that a transistor was possible with SiC because it’s a very difficult device. Even though everything suggests you can make it work in the same way the silicon industry would normally work with it, as a material, it does not want to change at all. You can’t tune it.”

The return

PV industry veterans may recall that the earliest PV inverters began to use SiC in the early 2010s, when the PV market first flourished. “With silicon carbide PV inverters in that time, it was possible to achieve higher efficiencies in the energy conversion. Accordingly, you could simply compensate with a lower number of [relatively expensive] PV panels installed, delivering overall savings,” explained Friedrichs.

“Then, with the subsequent drop of panel prices, the use of SiC became almost obsolete … only later with the availability of SiC MOSFETs, did a renaissance start in around 2016. PV inverter manufacturers wanted to use SiC again, in the MPPT-trackers, as SiC enabled much higher channel switching frequencies. This made systems small, lighter, and more cost effective.”

SiC advantages

SiC as a semiconductor is at its best when compared to pure silicon, as it comes to a mix of high power and higher switching frequencies. This is especially the case for the conversion from DC to DC in inverters, where it creates a significant advantage. The last point, for the conversion from DC to AC in inverters, creates a significant advantage.

Whereas IGBTs use around a 16kHz switching frequency, SiC MOSFET inverters switch at around 50kHz and higher. While higher frequencies have many benefits for inverters, the biggest benefit is a reduction in size of an inverter’s passive magnetic components, including choke coils and capacitors, dropping weight by as much as 50%.

The SiC promise for PV inverters has swiftly reached market maturity, well beyond prototypes and low-volume production of the late 2010s.

Early starters

Matthias Haag, head of R&D at Kaco New Energy, a Siemens company, told pv magazine that the company was a pioneer in the use of SiC switches in the solar industry, going beyond the more common use of SiC diodes. Kaco first introduced the SiC-based Blueplanet 125 TL3 string inverter in 2018, after three years of development, beating SMA by several months.

“[We] pioneered the industry here, launching the first inverters with SiC switches (SiC diodes have been in use for about 10 years now). It took some convincing at the beginning, but in the meantime customers have recognized the advantages. And other manufacturers are also increasingly using SiC – not only in PV, but also in e-mobility and storage applications, for example,” said Haag.

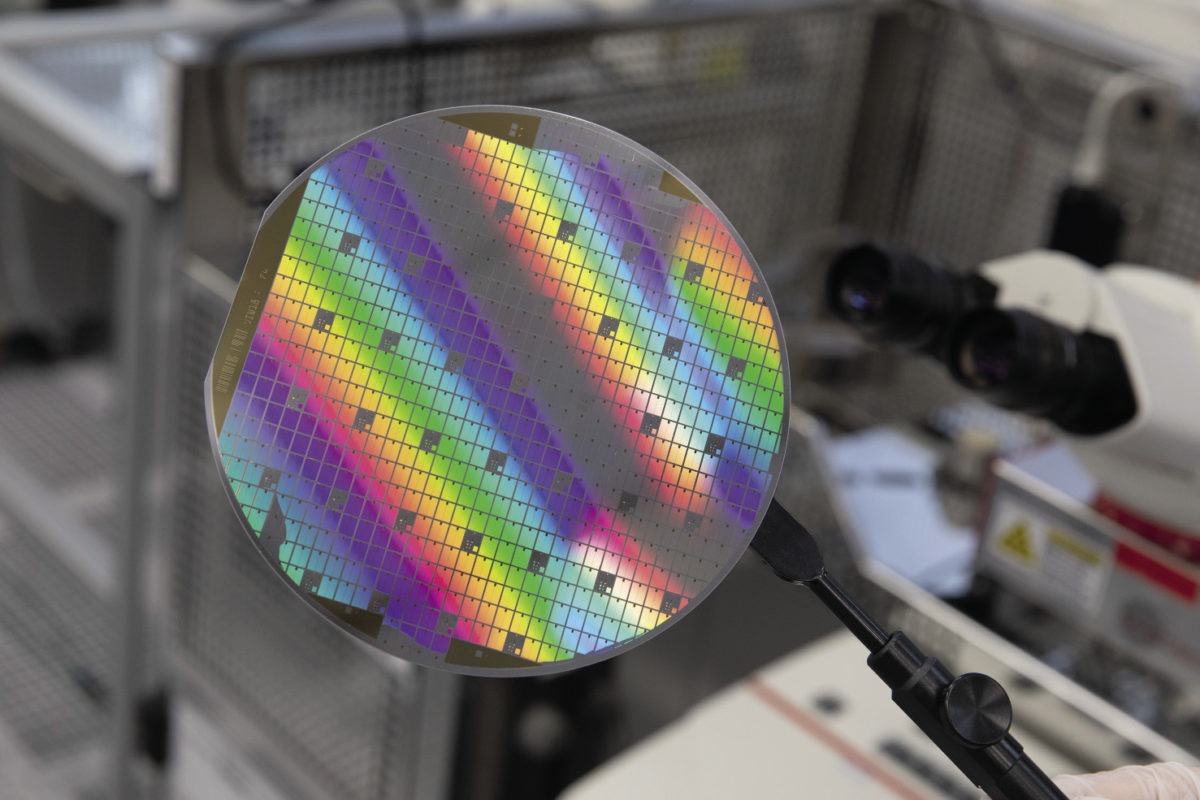

The challenge for semiconductor foundries has been price: the new technology and materials have been expensive. SiC fabs are migrating from 6-inch (150mm) to 8-inch (200mm) wafers, but at considerable cost.

A spokesperson at Bosch confirmed that the company announced its entry into this SiC chip development and production for the first time in 2019.

EVs + SiC = PV?

The timing of SiC coming to solar closely follows the automotive industry, and its increasing use of SiC in EVs. The Bosch spokesperson noted that the increased efficiency in SiC power electronics meant “motorists can drive 6% further on a single battery charge.”

But the development of better battery-electric cars wasn’t causal. “Time-wise it’s definitely correlated, but I don’t see technical correlation,” said Friedrichs. “Of course, the whole outlook for SiC and automotive is a big push for quantities and ramp-up plans for the future, which means market offerings become broader, and a steeper fall in cost can then be expected. But the storyline for solar is independent. The general worldwide trend to green energies is the big push.”

The rise in the use of string inverters in large solar plants has been another critical factor. Friedrichs explained that as installations moved from small installations towards enormous plants reaching the gigawatt range, so did the philosophy; from central inverters towards string inverters.

“With string inverters, the benefit of SiC is even bigger because weight, and volume are much more important than in the central inverter – basically because you need somebody to install it,” said Friedrichs. “And if you are below a certain weight for the PV inverter, you can do it by one or two people. To achieve the same power rating with silicon in the newest inverters would double the weight. It’s a simple driving post to use SiC in PV string inverters.”

Haag confirmed an ongoing commitment to SiC in the coming years, given it will remain competitive. “Additional SiC inverters will prevail precisely because of the price pressure, because SiC is a relatively young technology … and there is still potential for cost reduction,” said Haag. “And it is already the case that, although SiC components may still be more expensive per se, in relation to the entire device, costs can be saved in other areas, for example in chokes and heat sinks, which means that the end product is constantly becoming cheaper.”

Haag added that it can be said that “we will remain faithful to SiC in the coming devices for medium and higher power classes.”

What’s next?

Friedrichs said the next big SiC use case will be in storage, where efficiency improvements can reduce the necessary size of a battery, both in residential and larger installations. “In each and every PV system now you have storage, and in the storage system, you can save with the higher efficiency enabled by SiC. Between the panels and battery you need a DC-DC stage, and you usually have different voltage levels, and you need to convert what comes out of the panel,” said Friedrichs.

“The benefit of SiC here is that you can drop the losses by about 50%. Typically, people talk about efficiency and here it goes up from 98% to 99%, which doesn’t sound exciting. But if you take the other calculation, what is lost, now there’s 50% less losses.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.