From pv magazine International

Researchers from Deakin University in Victoria, Australia, have developed a lithium metal battery prototype which features electrolytes designed to be resistant to catching fire.

The breakthrough from Deakin’s Institute for Frontier Materials (IFM) is said to represent an alternative to the rechargeable lithium-ion batteries use in portable electronics, stationary energy storage and electric vehicles and is the culmination of more than 10 years’ work by electromaterials staff at the institute.

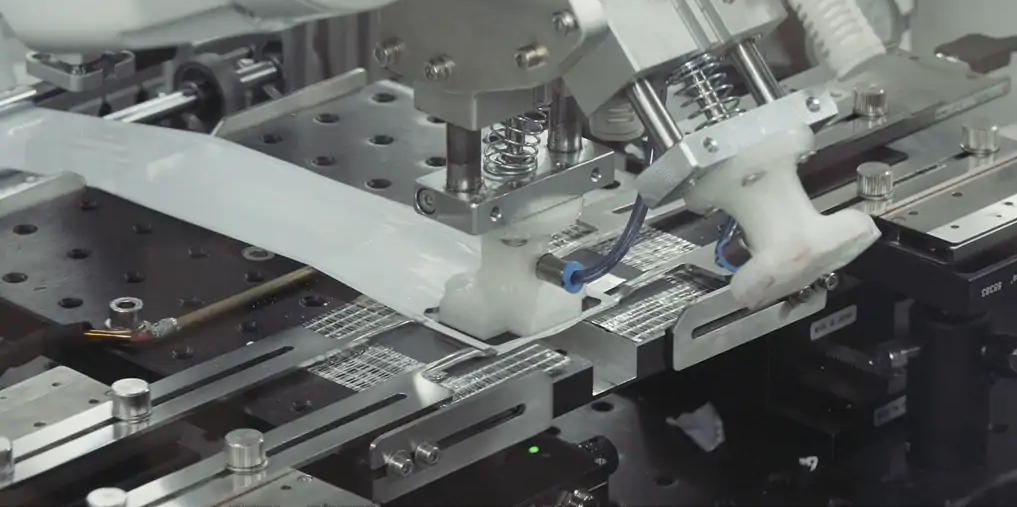

Patrick Howlett, director of the university’s Battery Technology Research and Innovation Hub (BatTRI-Hub) said a 1 Ah (amp-hour)-sized lithium metal pouch cell was the first device Deakin created using ionic liquid electrolytes which allow for better safety and high temperature and high voltage stability, to offer increased energy storage capacity.

The ionic liquid is a salt which takes liquid form at room temperature. Researchers at Deakin and Melbourne’s Monash University have been working for 30 years on the materials, which have begun to attract widespread interest in the battery community.

“Ionic liquids are non-volatile and resistant to catching fire, meaning that unlike the electrolytes currently used in lithium-ion cells – used by, for example, Samsung and Tesla – they won’t explode,” said Howlett. “Not only that, but they actually perform better when they heat up so there’s no need for expensive and cumbersome cooling systems to stop the batteries from overheating.”

Changing features

However, it is an outstanding ability to cycle energy-dense lithium metal electrodes which inspired the research effort. IFM research fellow Robert Kerr, who has worked on translating the materials into real devices, said changing battery materials could change key features of the devices.

“For example, if we change the electrodes to include lithium metal, we can increase the storage capacity for up to 50% longer run-times,” said Kerr. “When we change the electrolyte, it can give a higher discharge rate or allow the battery to operate at much higher temperatures – but the electrolyte must be compatible when in contact with the reactive lithium metal electrode. By choosing the right electrolyte chemistry we can completely avoid the catastrophic explosions caused by ignition of the volatile electrolyte when the cell is damaged or overcharged.”

While lithium metal batteries could offer far better energy density and much lower weight than lithium-ion technology – thanks to the replacement of heavier graphite with lithium metal as anode – lithium metals do not work well with conventional electrolytes. Another headwind for the innovative technology is the lack of knowledge about the best way to manufacture cells at practical levels for demonstration, given the use of lithium metal electrodes in lithium metal batteries is not common in the industry. The breakthrough has been described as “just a stepping stone on the way to 1.7 Ah cells, which are soon to be in production” nevertheless.

The project has been progressing at a rapid pace since the formation of the Deakin BatTRI-Hub in 2016. The potential of ionic liquid electrolytes is also being explored under a separate three-year project run by IFM and BatTRI-Hub with chemical manufacturer Boron Molecular – which was spun out of the federal Commonwealth Scientific and Industrial Research Organisation – and technology company Calix.

The project, which received AU$3 million (US$1.9 million) from the Australian government’s Cooperative Research Center Projects program last year, aims to develop high performance, low-cost, fast charge and discharge lithium-ion hybrid batteries based on nano-active electrode materials and ionic liquid electrolytes. It will explore the use of CalixFlash Calcination technology to produce customized micron-sized nano-electroactive materials for intercalation-based anodes and cathodes. That would be integrated with optimized ionic electrolytes developed with Boron Molecular and Deakin, to make up to 10 kWh battery pack prototypes at Deakin, through the Bat-TRI-Hub.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.