Ahead of the launch of its MG ZS electric car in India, British carmaker MG Motor has partnered with EV charging infrastructure and Li-ion battery solutions provider Exicom Tele-Systems on end-of-life use of electric car batteries.

Under the partnership, Exicom will recycle MG ZS EV batteries, at the end of their useful life, for use in a host of non-automotive applications such as home inverters, commercial & industrial UPS, and renewable energy storage.

MG Motor’s partnership with Exicom on recycling for Lithium batteries is aimed at ensuring safe disposal of EV batteries while addressing concerns about the raw material supply.

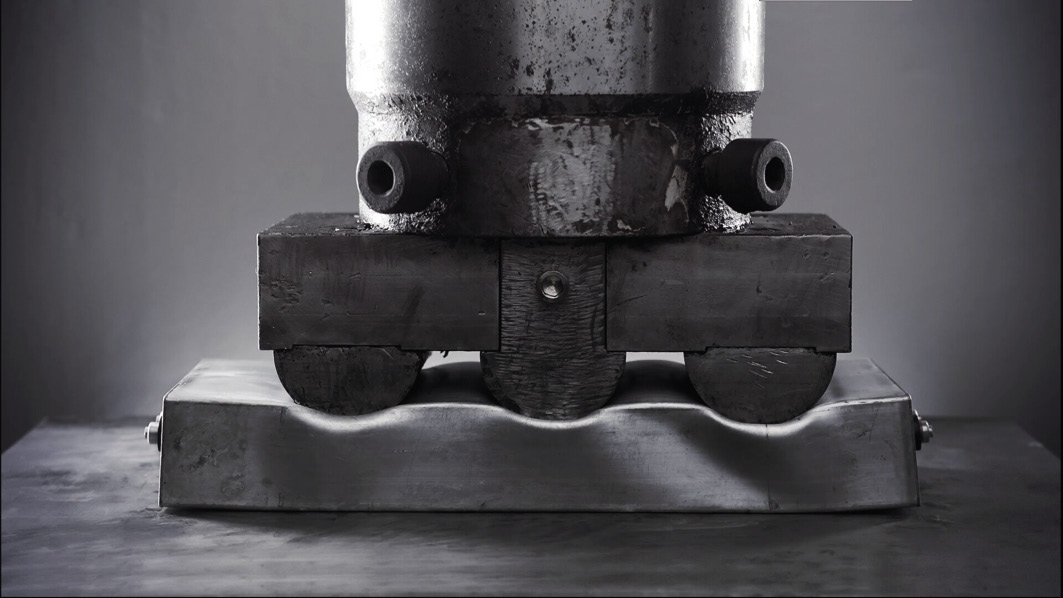

The ZS EV’s battery packs, at the end of their useful life, will be put through a controlled process of evaluation, disassembly, and repackaging to design custom battery packs for non-automotive applications.

Speaking on the tie-up, MG Motor India President & MD Rajeev Chaba said, “Over the past few months, we have worked towards creating the right ecosystem for our customers ahead of the launch of the ZS EV, including charging infrastructure and busting common myths around EVs. Another question which people have is “What happens to the EV battery after the product lifecycle ends.” Our latest partnership focuses on second-life applications for used EV battery packs, to ensure environment-friendly battery disposal.”

Exicom Tele-Systems MD Anant Nahata added, “Making electric mobility mainstream is one of the biggest challenges and opportunities we face. E-mobility also represents an important opportunity to overhaul our energy infrastructure and make necessary investments in renewables and new grid technologies.”

Tata Motors’ battery recycling plans

Earlier this year, Tata Chemicals—part of the over US$ 100 billion Tata Group which has launched electric cars through its arm Tata Motors—announced commencement of the commercial recovery of cathode active materials from spent lithium-ion cells/batteries.

“Li-ion battery recycling recovers valuable metals like lithium, cobalt, nickel and manganese at 99% plus purity within Industry leading levels of yield. As a result, we will reduce environmental pollution, save energy and natural resources by extracting fewer raw materials from the earth”—read a press statement by the company.

The recycling operations are carried out at a 3P facility located near Mumbai. The operations, launched at pilot scale, have successfully recycled the spent Li-ion batteries and Tata Chemicals endeavors to scale it to recycle 500 tonnes of spent Li-ion batteries.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.