BC Jindal Group announces INR 15,000-crore investment in solar and battery manufacturing

The BC Jindal Group has unveiled plans to invest INR 15,000 crore by 2030 to establish multigigawatt-scale manufacturing capacities for solar cells and modules, battery cells and packs, and solar glass.

IIT Kanpur, Mars Antennas partner on smart EV charger and hybrid inverter development

The Indian Institute of Technology Kanpur (IITK) has signed a Memorandum of Understanding (MoU) with Mars Antennas & RF Systems to collaborate on the design, development, fabrication, and testing of smart electric vehicle (EV) chargers and smart hybrid inverters for energy storage system applications.

Budget 2025 expectations of the Indian renewable energy industry

Regulatory and fiscal incentives to set up specialized labs in collaboration with leading international and domestic research institutions, reduction of Goods and Services Tax (GST) on turbines and solar modules, and ISTS charges waiver extension are on the budget wishlist of the renewable energy industry in India.

Lithium battery recycler Attero achieves ISO 14064 certification for GHG emissions verification

Attero is the first Indian company in the e-waste recycling industry to secure the ISO 14064 Certification for GHG Emissions Verification.

GFCL EV raises INR 1,000 crore to scale its battery materials capacity

GFCL EV will utilize the funds to scale its battery material capacities as it looks to capitalize on large-scale global opportunities in the electric vehicle and energy storage system space.

Jindal India Renewable Energy enters battery storage systems, targets 5 GWh cell capacity by 2027

Jindal India Renewable Energy plans to build 1 GWh battery pack assembly line by 2025. It aims to become an end-to-end player in energy storage systems with 5 GWh cell capacity by 2027.

Enerpoly opens zinc-ion battery factory in Sweden

Sweden’s Enerpoly has ambitious plans to make its 6,500m2 plant the center of global and European zinc-ion battery innovation. It is aiming for final capacity of 100 MWh annually by 2026.

Foxconn mulling battery energy storage unit in India

Taiwanese electronics manufacturer Foxconn (Hon Hai Technology Group), which is working on lithium ferro phosphate (LFP) and solidstate batteries, is exploring production of electric vehicles and battery energy storage systems in India.

Amara Raja Energy & Mobility Q1 profit rises 23% yoy

Amara Raja Energy & Mobility Ltd has reported a standalone total income of INR 3,156.74 crore and a net profit of INR 244.55 crore for the first quarter (April-May-June) of FY 2024-25.

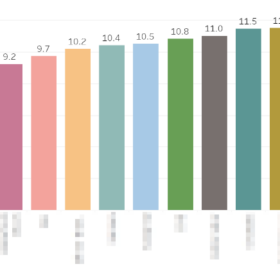

Data reveals dominant players in Australian battery market

Analysis by solar and storage market consultancy SunWiz has identified the most popular brand of battery energy storage systems in the Australian market with Chinese manufacturers leading the way.