pv magazine: While the government aims to make India a 100% electric vehicle (EV) nation by 2030, there are doubts this can be achieved. What are the main challenges in achieving this target?

Dr Rashi Gupta: Currently, the challenge is the infrastructure. It is a known fact that any vehicle will only run the distance for which its fuel tank can support. To have a balance between cost of the vehicle, charging time and efficiency, EVs have a limited energy capacity, which gives a limited mileage. Given this situation, there is a strong need for fast chargers, which are found as frequently on the roads as petrol/diesel fuelling stations currently are.

Another issue that could come up would be managing the surge power drawn from the grid, given the number of vehicles that would be fast charged together. This power drawal could be locally concentrated or widespread, the effects of which would be different and, if not managed correctly, could be catastrophic.

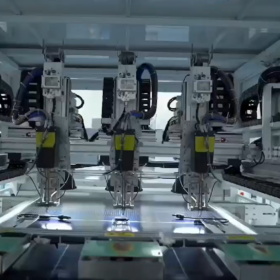

Image: Vision Mechatronics

What’s the lithium-ion battery manufacturing landscape for EVs currently like in India?

Currently, there are no cell manufacturers in India. Though Indian Space Research Organisation (ISRO) and Central Electro Chemical Research Institute (CECRI) have come with technologies that could aid the manufacturing of cells in India, it’s still a long term plan. India lacks many raw materials needed for the batteries that are used in EVs.

Does the government have a policy in place for Li-ion battery manufacturing? Are there incentives?

None that I’ve come across, but we are positively looking forward to it with the National Energy Storage Mission. With the kind of attention Li-ion battery manufacturing is getting of late, it should not be long before things fall into place.

Does India have the necessary resources and expertise?

Resources in terms of land, electricity and labour don’t pose a concern. Raw materials, on the other hand, would be a small hitch that can be overcome easily.

Which countries can help India to become independent in Li-ion manufacturing?

There are newfound lithium reserves in Bolivia and they are very keen on allowing India to tap into them. We at Vision Mechatronics are also actively involved for this partnership as it would help India meet its targets set for the energy storage segments.

To achieve scale of economy, demand volumes matter. Is the demand right, considering that there are not many EVs on the Indian roads?

There is demand for electric vehicles as people do understand the need for them. They are pro the electric vehicles, but are waiting for the infrastructural development to finish.

What kinds of vehicles are likely to contribute to Li-ion battery demand the most? Considering that there are a variety of e-vehicles, what are the challenges for battery manufacturers?

A major segment of transportation in India has, and will always be, public transport, which comprises buses, rickshaws and cabs. Given the fact that buses are still the most economic method of transport after trains (may vary in some cases), electric buses would constitute a major chunk of the battery demand. Given the variety of e-vehicles, the only challenge that battery manufacturers can have is the inter-compatibility.

While auto makers have aggressive plans for EV sales in India, why are they shying away from taking the plunge into battery manufacturing?

The auto industry is preparing for EVs and waiting for the right infrastructure and the policy framework to set in before entering the Indian market. As the technology upgrades, definitely the cost would reduce, making it more affordable and faster to adopt EVs. Battery manufacturing is a very skilled and highly technical field, and is an independent business vertical in itself. I feel playing on one’s core strength is the best business model.

Which battery technologies are the most suited for India?

Battery technologies with higher temperature ranges, like Lithium-Iron-Phosphate (LFP) and Lithium Titanate (LTO), are the most suitable for India, but at the same time it is very important to understand the right mix of technology for the intended application to arrive at perfect techno-commercial feasibility.

India lacks resources like lithium, cobalt, nickel, phosphorus and sulphur, but has iron, aluminium and graphite. So for a new technological development, we should look into developing chemistries with resources available and with least imports possible.

What are the opportunities available for companies looking to diversify?

There is a great opportunity for companies in the energy storage domain, but it is important to understand the right mix of the chemistry, its application, the process and certifications. The demand will certainly rise in the near future and India will have to build up the capability and the capacity to cater to this demand. Other than the cell and pack assembly manufacturing lines, companies can also look into ancillaries that are required to complete the Lithium batteries. This will also be a profitable business.

Going forward, what changes do you see, or would you like to see, in the Indian scenario for battery manufacturers?

The taxes should be reduced on batteries per se. Also, there must be some incentives from the government for huge investments in setting up the manufacturing plants, standardization and robust testing infrastructure.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Well documented interview. These clear indications shows how India should move forward in this area to become self reliant.