From waste to resource: Recovering critical minerals for solar and EV batteries

As India ramps up solar installations and EV deployments, the volume of end-of-life components will grow rapidly. If these are treated simply as waste, we create new environmental burdens and miss a chance to recover value. If, instead, they are viewed as sources of supply, they become part of the solution.

What will help India to reduce the $2 billion battery import bill?

India’s Production-Linked Incentive (PLI) programme for cell manufacturing has attracted investment into gigafactories and electrode production, but local manufacturing can only succeed if it has access to steady, domestic mineral feedstock. Recovered materials from end-of-life batteries can supply a meaningful share of that requirement, provided there is strong collection infrastructure, organised supply aggregation, and investment in processing technologies.

AGC, NPC developing new PV cover glass recycling tech

The Japanese companies announced a partnership to advance the recycling of solar panel cover glass for application in architectural flat glass production.

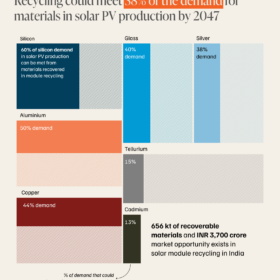

Solar module recycling offers an INR 3,709 crore market opportunity in 2047: CEEW

India is estimated to generate over 11 million tonnes of solar waste by 2047. Recycling could meet up to 38% of India’s future solar material needs.

OMC Power, Honda Motor partner on energy storage solutions from repurposed EV batteries

OMC Power, a distributed renewable energy (DRE) company targeting 1 GWp clean energy portfolio in India, and Honda Motor have partnered on innovative business models in energy storage and battery repurposing from the electric mobility ecosystem.

PV module recycling gains momentum as waste volumes surge globally

A comprehensive new report from IEA PVPS Task 12 reveals how countries around the world are managing the growing volumes of end-of-life solar modules, implementing regulations and scaling recycling infrastructure to handle the expected increment in PV waste over the coming decades.

How startups are driving affordable battery solutions for Bharat

With lithium being an imported raw material, recycling and repurposing of lithium batteries once they have completed their lifecycle is paramount. In line with this, Indian startups have come up with several ingenious business models for second-life applications that repurpose EV or lithium-ion batteries for stationary storage.

Can India cope with the growing tide of battery waste?

The world is projected to retire over 11 million tonnes of lithium-ion batteries each year by 2030. India may contribute nearly 2 million tonnes by 2030, not only due to electric vehicles, but also because of an exponential level of consumption of consumer electronics and stationary storage.

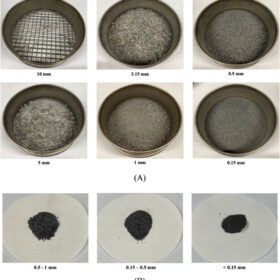

New sieving tech for solar cell silver recovery

Researchers at University of New South Wales have reported details about a novel sieving-aids technology that improves the separation of metal fragments from other components when recycling end-of-life PV panels. The patented process reportedly enhances the recovery of silver.

MIT-WPU researchers develop scalable solar PV waste recycling process

Researchers at MIT World Peace University (MIT-WPU) have developed an innovative process that not only enables recovery of valuable materials from end-of-life solar panels but also upcycles non-recoverable fractions into construction materials such as bricks, blocks, and aggregates. This dual approach prevents hazardous waste from entering landfills while reducing dependence on virgin raw materials.