Trontek enters residential energy storage market with 1.4 kWh and 2.7 kWh lithium battery systems

Trontek has entered the residential energy storage market with the launch of Powercube 1.4 kWh and Powercube 2.7 kWh lithium-ion battery storage systems that support both solar and grid charging.

Agratas advances construction at its Sanand battery facility

Agratas, the global battery business of the Tata Group, is rapidly advancing the construction work for its battery manufacturing facility in Sanand, Gujarat. This facility will have a planned annual capacity of 20 GWh in its first phase.

India could attract $4.1 trillion in green investments by 2047: CEEW

Around 92% of the required investments—about $3.79 trillion—would flow into the energy transition, spanning renewable energy, storage, clean mobility, and green hydrogen.

Oscal releases 2 kWh battery for home, off-grid, on-grid use

The Chinese company said its 2,016 Wh portable LiFePO₄ energy-storage system is expandable to 22,176 Wh with additional battery modules. It delivers 2,400 W output, offers 16 ports, app-based control, and includes built-in audio and lighting features for home, travel, and off-grid use.

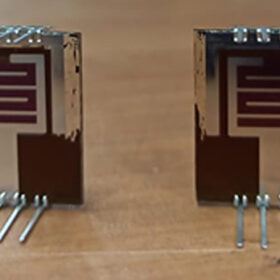

‘It’s not a matter of sodium versus lithium, we need both’

A US research team has developed all-solid-state sodium batteries that retain performance down to subzero temperatures. The systems utilize a special chloride-based solid-electrolyte-coated cathode.

Industry body IESA submits recommendations to strengthen battery recycling ecosystem

Industry body India Energy Storage Alliance (IESA) has called for clearly defined roles and responsibilities under the Battery Waste Management Rules, the adoption of global standards, recycled content targets aligned with emerging battery chemistries and domestic manufacturing, and support for eco-design to enable easier recycling.

India’s evolving battery landscape: An interview with Trina Solar’s Leo Zhao

Leo Zhao, Head of Energy Storage, Trina Solar Asia Pacific, speaks to pv magazine about why India is a strategic market for utility-scale energy storage, the latest trends and technology adoption, and Trina Solar’s plans for the market.

From waste to resource: Recovering critical minerals for solar and EV batteries

As India ramps up solar installations and EV deployments, the volume of end-of-life components will grow rapidly. If these are treated simply as waste, we create new environmental burdens and miss a chance to recover value. If, instead, they are viewed as sources of supply, they become part of the solution.

What will help India to reduce the $2 billion battery import bill?

India’s Production-Linked Incentive (PLI) programme for cell manufacturing has attracted investment into gigafactories and electrode production, but local manufacturing can only succeed if it has access to steady, domestic mineral feedstock. Recovered materials from end-of-life batteries can supply a meaningful share of that requirement, provided there is strong collection infrastructure, organised supply aggregation, and investment in processing technologies.

“Standalone battery storage is a strategic differentiator for us,” says Sunsure’s Kartikeya Sharma

Sunsure Energy, founded in 2014, has evolved from a solar developer into a clean energy solutions provider delivering integrated power solutions across solar, wind, and battery storage. Kartikeya Sharma, co-founder and chief business officer at Sunsure, speaks to pv magazine on the key trends reshaping India’s renewable energy landscape, the rising role of battery storage, and Sunsure’s plans for the market.