Environment ministry releases draft version of battery waste management rules

Establishment of an R&D cell for battery recycling and online tracking of the collection and re-processing of used batteries are highlights of the draft rules which seek to ensure safe disposal and organized recycling of batteries at the end of their life.

India’s future energy options all add up to coal, agree the experts

Panellists including a government representative and a member of the chief policy thinktank used by Narendra Modi agreed coal will continue as the staple source of Indian power into the mid century and technology should be employed to ‘clean’ it.

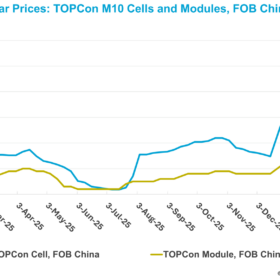

India’s lithium-ion battery imports increase fourfold in two years

China, Hong Kong and Vietnam are the top three nations exporting batteries to India. Chinese imports were worth $773 million in the last fiscal year with Hong Kong shipping $267 million worth and Vietnam $114 million, according to the Ministry of Commerce.

Li-ion Gigafactories: Niti Aayog seeks cabinet nod for Rs 7 billion annual subsidy proposal

Already approved by the finance ministry, the proposal aims to woo investors into setting up manufacturing units in India and lower battery costs with indigenization of technology. An aggregate manufacturing capacity of 50 GWh is planned to be set up over a period of 10 years, which would require investments worth Rs 355 billion.

Delta Electronics launches 22KW AC EV charger and 125KW string PV inverter

The wall-mount charger with a high power output of 22 KW AC maximum reduces electric vehicle charging time by up to 70% in comparison to common 7KW AC chargers. The 125 KW string inverter—a cloud-connected three-phase solution—enables cost-efficient decentralized photovoltaic systems for both ground-mounted and large commercial applications.

Pinnacle and China’s Phylion launch lithium-ion battery assembly unit in Maharashtra

Madhya Pradesh based Pinnacle Industries–a commercial vehicle components manufacturer–plans to roll out electric vehicle battery packs with Phylion cells and semi-knocked-down kits.

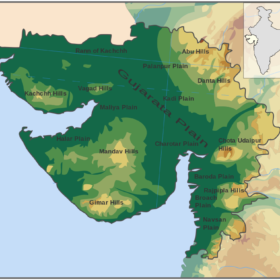

AEPPL to invest Rs37.15 billion in second phase of lithium battery plant

The joint venture between Japanese majors Toshiba, Denso and Suzuki will make the investment in the Gujarat plant over the 2021-25 period, having pumped Rs12.5 billion into the first phase of development.

ISRO transfers space-grade Li-ion cell technology to BHEL

While BHEL will primarily produce Li-ion cells for ISRO and other strategic sector programmes, it can also suitably modify the space-grade cells—and thus leading to cost reduction—to meet the requirements of commercial applications.

Government in the process of finalizing new energy policy: NITI Aayog Additional Secretary

Apart from thrust on energy efficiency and clean energy, the new policy will focus on Make in India for cells used in electric vehicle batteries and measures for demand creation and incentivizing investments.

MG Motor partners Exicom on EV battery recycling

Exicom Tele-Systems will recycle electric vehicle batteries at the end of their lifecycle to develop custom battery packs for non-automotive applications such as home inverters, commercial & industrial UPS, and renewable energy storage.