‘Least-cost’ model for compressed air energy storage

Stanford University researchers have created a model to assess how much compressed air storage capacity might be needed for the deep decarbonization of power systems, while compensating for the variability of wind and solar-based power systems. They applied the model to California’s energy system and found that compressed air could be very competitive on a dollars-per-kilowatt-hour basis.

Australian manufacturer reveals 1 MWh sodium chloride battery design

Altech Batteries, a battery tech company in Western Australia, has included “game-changing” sodium chloride technology in its new battery 1 MWh GridPack. It said it expects the new systems to be up to 40% cheaper to produce than dominant lithium-ion alternatives.

India’s energy transition presents $25 billion annual investment potential: Avendus Capital

India attracted around $10 billion of annual investment in the renewable energy sector over the last five years. High economic growth and a stable commitment to decarbonization have drawn the attention of major organizations and investors from around the world.

The case for using gas-based plants to serve peak power demand

Using some of India’s existing gas-based power capacity as peaking plants would be more economical than the other options in the short-term market for peak power supply. Gas-based power plants can provide ancillary services to maintain the grid’s power quality, reliability, and security as renewable energy capacity increases, says a new report by IEEFA.

Amp Energy to build 720 MW of renewable energy projects in Andhra Pradesh

Amp Energy has committed to building 720 MW of wind, solar, wind-solar hybrid, floating solar, and energy storage projects in Andhra Pradesh with an estimated investment of approx Rs 5,800 crore over the next 3-5 years.

Thermax enters green hydrogen market in partnership with Australia’s Fortescue Future Industries

Pune-based Thermax has partnered with Australia’s Fortescue Future Industries to explore opportunities for the joint development of fully integrated green hydrogen projects for commercial and industrial customers in India. They also contemplate collaborating on electrolyzer and subsystem manufacturing facilities to support green energy projects in India.

Adani to develop 15 GW of renewable energy projects in Andhra Pradesh

Adani Group has committed to building 15 GW of renewable power projects in Andhra Pradesh, while Reliance announced its 10 GW solar plans for the state. Avaada, Greenko, Indosol, and ReNew have also pledged massive investments into the state’s renewables sector.

Greenko raises $700 million in equity funding for pumped storage projects

The Hyderabad-based developer will use the amount towards the capital expenditure of more than 25 GWh of pumped storage projects.

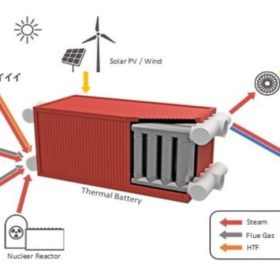

New thermal battery offers fast, efficient performance at low cost

US engineers have built a scalable thermal energy storage prototype system that combines the best latent and sensible heat transfers. The technology, which is now market-ready after three years of testing, consists of engineered cementitious materials and thermosiphons in a combination that enables fast, efficient thermal performance at low cost.

Karnataka, Gujarat lead the way in transition to clean electricity

A joint study by IEEFA and Ember analysed 16 Indian states on their preparedness to shift away from fossil-fuel-based power, ability to incentivize greener market participation, power system’s reliability, and policies pushing for power sector decarbonization. It shows Karnataka and Gujarat fare well in progress towards clean electricity transition.