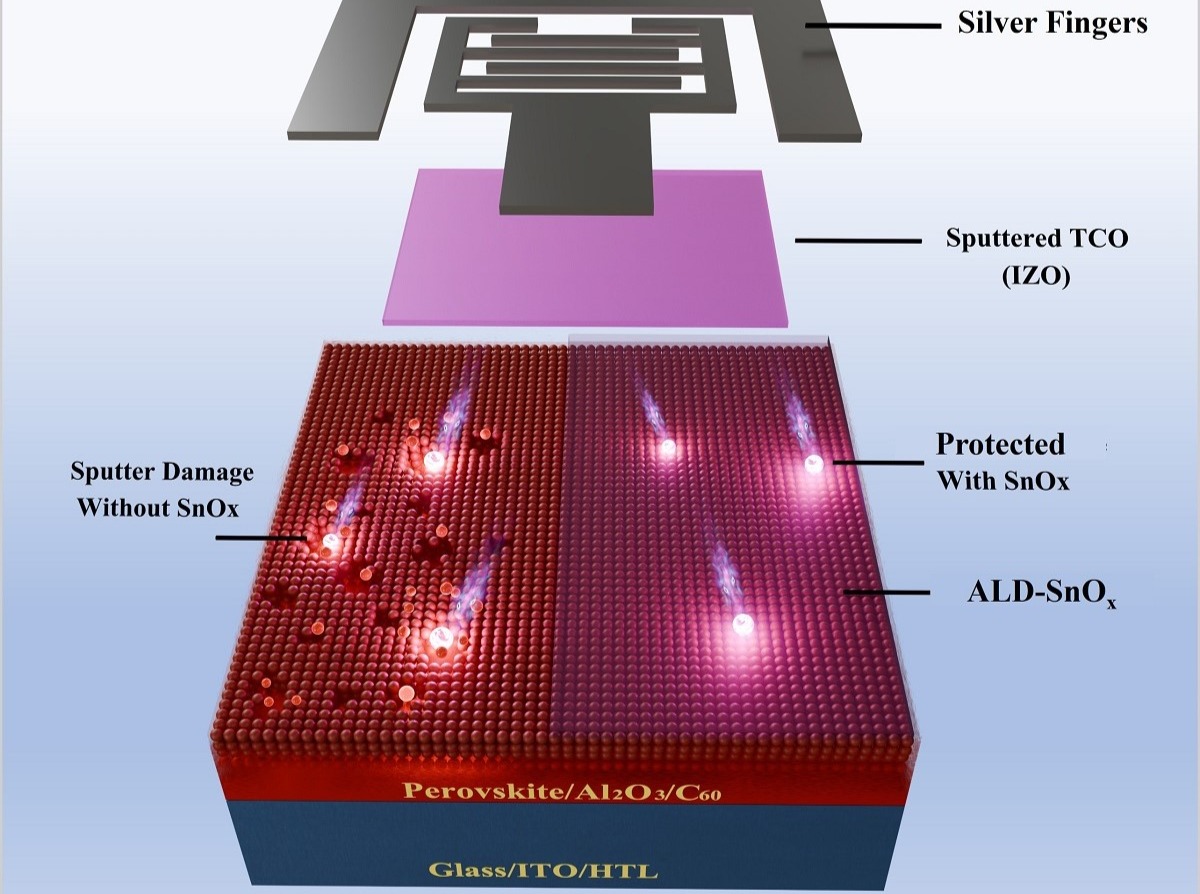

A research team from the Indian Institute of Technology Bombay has demonstrated an atomic layer deposition (ALD) method within a lower temperature process to apply a buffering layer of tin oxide (SnOx) thin film to protect perovskite and transport layers from damage during the transparent conducting oxide sputtering process.

Sputtered transparent conducting oxide (TCO) is used to enable perovskite tandem and bifacial perovskite solar cells (PSC). Sputtering, however, can cause high-energy particles and ultraviolet (UV) light to damage the underlying perovskite and organic charge-transporting layers.

“The major focus of the work was the detailed recipe for low temperature atomic layer deposition (ALD) of a SnOx interlayer on the perovskite/buckminsterfullerence (C60) stack at low temperatures to prevent sputter damage,” Dinesh Kabra, corresponding author of the research, confirmed to pv magazine. “This SnOx interlayer with optimal density and thickness is key for greater yield.”

Its effectiveness was demonstrated in an inverted 1.08 cm2 perovskite solar cell that achieved 16.53% efficiency. In the inverted, or p-i-n structured cell, illumination is through the hole transport layer (HTL) side. In the conventional halide PSC, n-i-p architecture, the solar cell is illuminated through the electron-transport layer (ETL).

In the study, the structural, optical, and compositional properties of ALD-SnOx thin film as a function of growth parameters were examined. The ALD-SnOx film properties were finely tuned by varying the ALD recipes.

Parameters such as deposition temperature, precursor exposure, and purge times on the growth behaviors were optimized.

“The optimization of process time of ALD facilitates a window to protect degradation of underlying thermally sensitive organic layers in PSC,” said the scientists. It enabled films with a high average transmittance of over 94.8% and 350-1200 nm thickness, a refractive index of 1.78 to 1.95, negligible extinction coefficient, varied composition of tin oxide (x = 1.7–1.95), smooth surfaces with a roughness of 0.18-0.28 nm, and high mass density >5.6 g/cm3.

“We successfully achieved amorphous, dense, smooth, highly transparent, and stoichiometric ALD-SnOx thin films with suitable refractive index values,” said the team.

It then tested the optimized SnOx buffer layer approach in a near-infrared (NIR) transparent inverted PSC. The resulting NIR-transparent p-i-n perovskite solar cells had a power conversion efficiency of 16.53% based on 1.08 cm2 devices.

The stack was as follows: glass substrate, ITO, Me-4PACz, perovskite (FA0.83Cs0.17Pb(I0.8Br0.2)3), aluminum oxide (Al2O3), the 6 nm SnOx interlayer on buckminsterfullerence (C60), indium doped zinc oxide (IZO), silver (Ag) finger and busbar.

It was compared to 0.175 cm2 control devices with an opaque stack as follows ITO, Me-4PACz, Perovskite (FA0.83Cs0.17Pb(I0.8Br0.2)3), Al2O3, C60, BCP(6 nm), Ag. To assess the impact of ALD-SnOx, they replaced the 6 nm BCP layer with an ALD SnOx layer.

The team concluded that the fabrication of “highly efficient devices provides the pathways for bifacial, four-terminal and two-terminal tandem cells, and opaque surface solar cell technologies.”

The solution found by the IIT was described in the study, “Optimization of Atomic Layer Deposition Process of Tin Oxide Thin Films for Near-Infrared-Transparent Halide Perovskite Solar Cells,” published in ACS Applied Energy Materials.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.