From pv magazine Global

Researchers from the University of Genoa and Italian aerial inspection company Wesii have compared the aerial infrared (IR) thermographic results of PV plant inspections by either classical thermal cameras mounted on unmanned aerial vehicles (UAVs) or highspeed thermal cameras mounted on an airplane. Their research included an economic analysis of both remote sensing-based approaches for diagnostic and fault detection.

“The use of aerial drones expedites the detection of faults within a large solar PV plant. However, if the IR camera is not fast, the drone’s moving speed must be relatively low to avoid smearing effects,” the group explained. “An airplane can cover a very large area in a shorter time, resulting in more cost-efficient flights. On the other hand, due to the carrier speed, the IR camera requires high resolution and a higher number of acquired frames per second. These are typically found in cooled thermal cameras, which are much more expensive than standard uncooled cameras.”

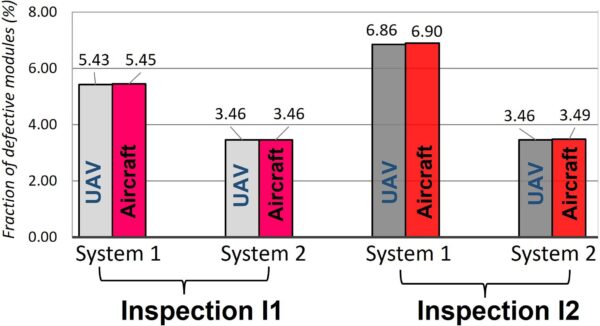

For their experiment, the researchers used the DJI Mavic 2 Enterprise Advanced UAV and a human-crewed airplane P2006T SMP. Both have surveyed two PV plants in northern Italy twice and at the same time. System 1 comprises 4347 polycrystalline silicon PV modules, while System 2 comprises 4158 polycrystalline silicon PV modules. Both have an installed capacity of about 1 MW.

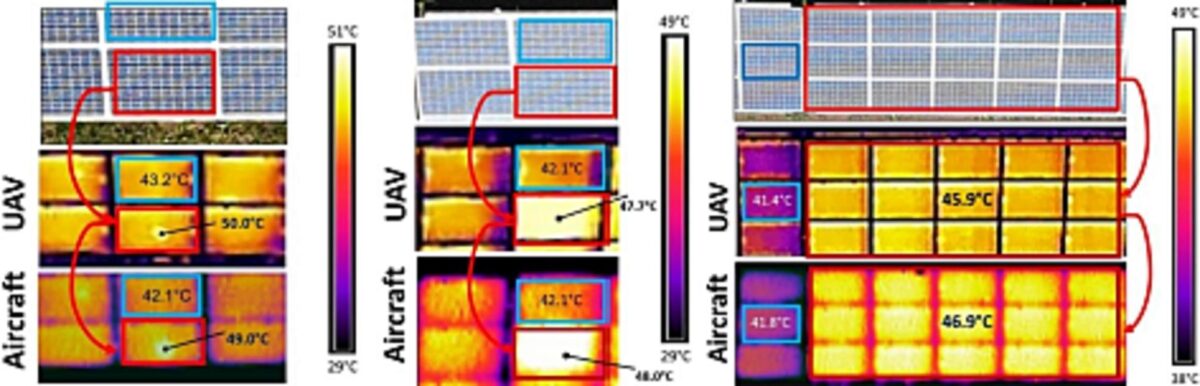

In all of its flights, the UAV has used a DJI M2EA thermal camera having an uncooled 640 × 512 microbolometer detector, operating in the 8–14 μm wavelength range. The human-crewed airplane used in the first flight a FLIR A8580 with a 1280 × 1024 cooled sensor operating in the 7.5–12.5 μm wavelength range, while in the second flight, it used a FLIR X8581 InSb, 1280 × 1024 cooled sensor operating in a different wavelength range of 3–5 μm.

Image: Università degli Studi di Genova, Thermal Science and Engineering Progress, CC BY 4.0 DEED

“The rationale behind using a different thermal camera during the second airplane inspection was to permit the comparison between thermal patterns obtained by two IR cameras with different spectral responses, specifically the long infrared wavelength range (LW) for the drone and the medium infrared wavelength range (MW) for the airplane,” the academics explained.

Collected visual and thermal images were processed on a computer, identifying and categorizing thermal abnormalities in the PV plants.

“Regarding the most critical defects, such as defective substring, entire module, and a string of modules, 99.6 % of them were detected by both aerial platforms. Furthermore, 87.3 % of modules with single or multiple hotspots, identified by UAV surveys, were also detected by airplane inspections,” the researchers emphasized. “Overall, about 98 % of thermal defects captured by drone inspections were confirmed by airplane inspections, with only a 0.23 K difference in temperature delta.”

The group concluded that the results show excellent agreement, which is encouraging regarding using an aircraft. With those results, the scientists went on to do a comparative analysis of costs.

Image: Università degli Studi di Genova, Thermal Science and Engineering Progress, CC BY 4.0 DEED

“While UAV-based inspections, which are the market standard, entail daily equipment and workforce costs not as high as those of the airplane, the latter platform, however, allows for coverage of a larger daily area,” they said. “This implies that a threshold value, based on the size (and capacity) of the inspected plants, is likely to determine which technique is more economically viable.”

Per the Italian test case, the daily cost of a UAV is €800 ($876), inclusive of the expenses for the operators and the uncooled thermal camera rental. Furthermore, the rental cost for the aircraft, including the pilot, is €2,700 per day and €120 for the cooled camera. However, it can be assumed that the UAV platform can inspect a maximum of about 20 MW in a single working day, while the airplane can do 300 MW.

“The results show that for inspections of any plant requiring more than two working days, and that the use of the airplane is economically more convenient,” the academics said. “Furthermore, the threshold decreases (and conditions for aircraft use become more favorable) if the same amount of PV power is spread across a cluster of smaller plants in the same region.”

The results were presented in “Infrared thermography monitoring of solar photovoltaic systems: A comparison between UAV and aircraft remote sensing platforms,” published in Thermal Science and Engineering Progress.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Glad to see focus on the O&M aspect of “Passive” PV Systems that are supposed to run “on their own” for Decades.

However, there is always a gap between the real and predicted world… as here… and this “research” confirms this quite effectively … 👍🏽👍🏽👍🏽👍🏽👍🏽👏👏👏👏