Researchers at Japan’s National Institute of Advanced Industrial Science and Technology (AIST) have fabricated lightweight, curved crystalline silicon (c-Si) solar modules with a front cover made of polyethylene terephthalate (PET) instead of conventional glass material.

“Our research demonstrates that crystalline silicon solar cell modules with a PET film cover are highly reliable under high-temperature and high-humidity conditions,” the research’s corresponding author, Tomihisa Tachibana, told pv magazine. “While we haven’t yet calculated the system cost, we anticipate that the weight reduction will likely lower transportation and installation expenses.”

In the paper “Development of lightweight and flexible crystalline silicon solar cell modules with PET film cover for high reliability in high temperature and humidity conditions,” published in Solar Energy Materials and Solar Cells, the Japanese group explained that PET films represent a viable alternative to glass covers, due to their excellent electrical insulation and optical transmittance.

The scientists built the modules with 156 mm2 × 156 mm2 c-Si polycrystalline aluminum back surface field (Al-BSF) structured solar cells with a thickness of approximately 250 μm. “The strings at the busbar were connected by machine soldering, and the strings of the four-cell modules were connected in series by hand soldering,” they noted.

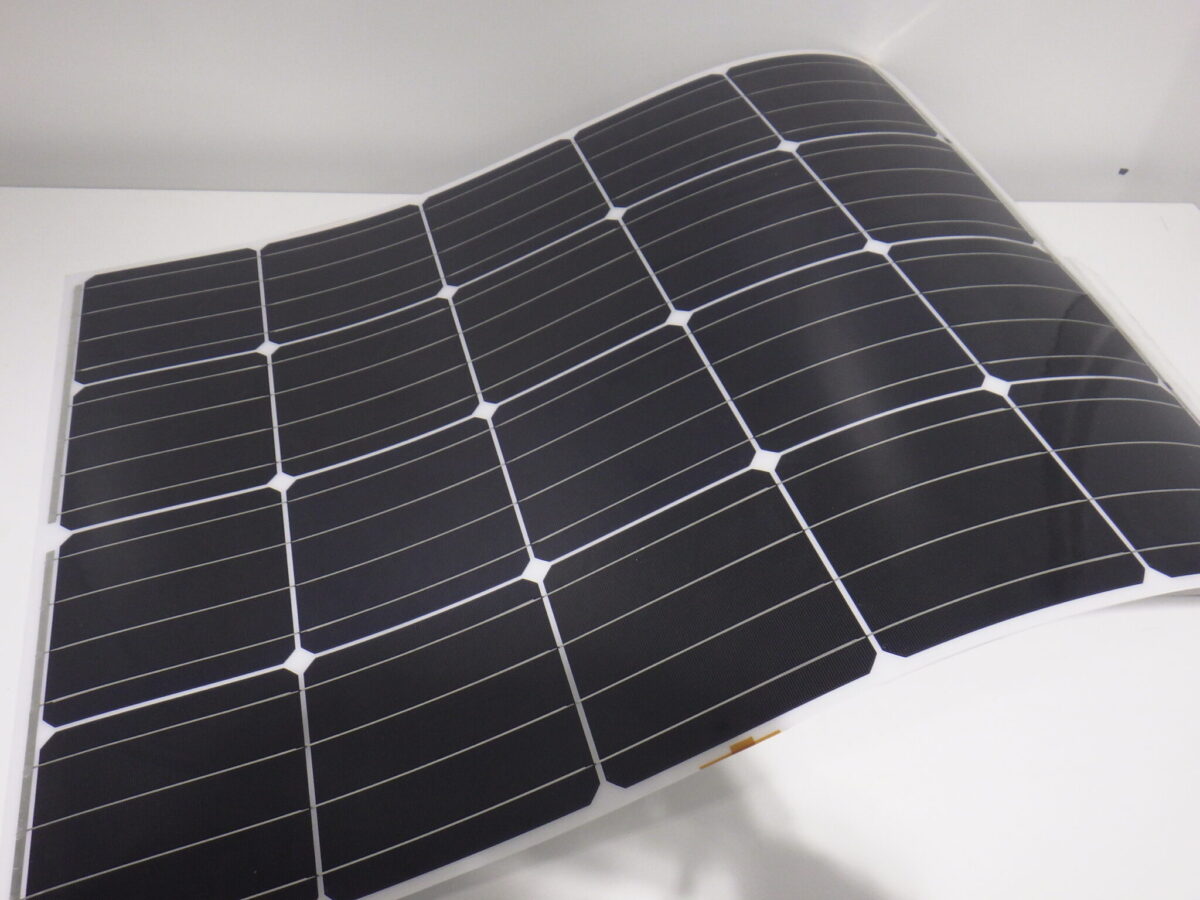

They used a 0.025 mm-thick PET film for both the module’s front cover and the backsheet and encapsulated the panels with ethyl vinyl acetate (EVA). “The module structure was PET/EVA/c-Si cell/EVA/PET or Backsheet,” they added.

The team compared the thermal behavior of the new module with that of a reference panel using a 3.2 mm-thick glass as the front-cover material and found the former exhibited greater flexibility than that fabricated using glass.

It also ascertained, however, that the module based on PET has a 10% lower current value, as the PET film, unlike the glass, has an anti-reflectance structure. The voltage and fill factor values were found to be approximately the same as those of the benchmark glass module. “The absence of a glass cover also imparts the fabricated modules with flexibility, and no cracks or other defects were observed after the modules were placed on and then removed from a measurement stage with a 200 mm radius of curvature,” it further explained.

The scientists emphasized the modules with a PET film cover also have the advantage of reduced weight, approximately “one-fourth per cell size”, which they said makes them ideal for installation in locations with loading restrictions.

They also tested the modules in a series of damp heat (DH) tests at 85 C and under 85% relative humidity and found that the glass-based panel showed degradation in the fill factor and current values after 3000 h because of corrosion of the silver (Ag) front electrodes. “By contrast, the lightweight modules (PET/Backsheet or PET/PET) showed only slightly diminished I–V properties, with about 10% degradation from the initial value after 6000 h of DH testing,” they stated.

The research group believes the PET-packaged modules with their impact-absorbing capacity may accelerate solar deployment in areas such as weight-limited factory roofs and agricultural applications.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.