Indian Institute of Technology Kanpur (IIT Kanpur) will leverage UK-based H.E.L Group’s battery testing technology and expertise in battery performance and application safety in its research work to understand the testing requirements for larger batteries. The two parties signed an agreement on this collaboration recently.

“The collaboration with IIT Kanpur is part of a national initiative in sustainable energy led by IIT Kanpur to develop new testing laboratories to conduct research into battery storage, new chemistry development and thermal characteristics. The research will support joint projects with industry partners on protocol development and technical advisories,” read a joint release by H.E.L Group and IIT Kanpur.

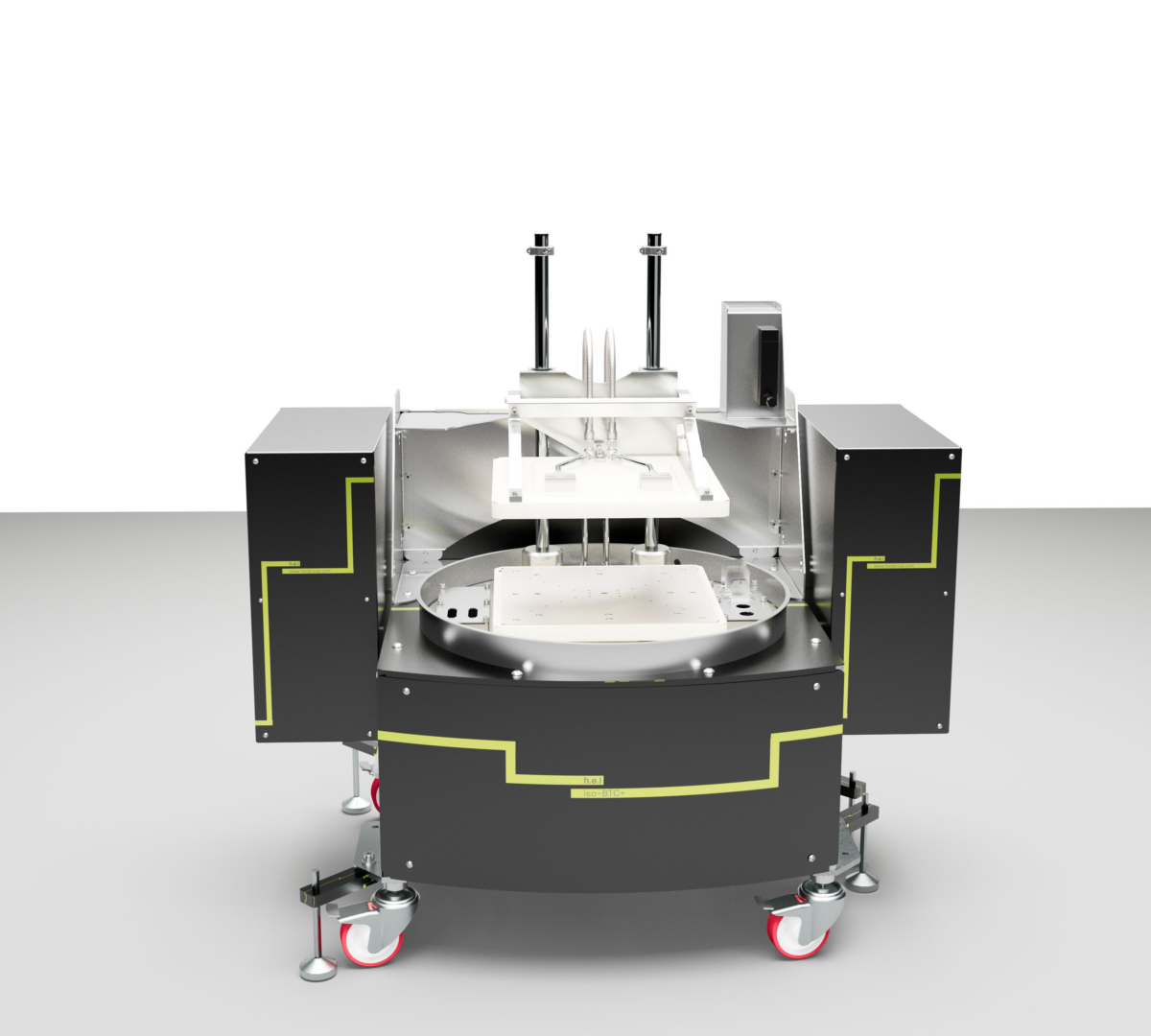

H.E.L develops and manufactures innovative laboratory tools for process optimization, safety, and scale-up. It will provide IIT Kanpur with its Iso-BTC+ non-abusive and non-destructive isothermal calorimeter designed to characterize thermal behavior of battery cells during charge and discharge testing, leading to enhanced performance, lifespan and safety.

Raju Kumar Gupta, professor at IIT Kanpur, said, the Iso-BTC+ will enable IIT Kanpur to measure heat release profiles of large batteries during charge and discharge. The equipment will give extremely tight control of the battery temperature and will enable IIT Kanpur to obtain thermal characteristics of cells during operation.

“The software-integrated battery cycling function will allow us to understand how charge/discharge profiles affect heat generation. The iso-BTC+ will give us a complete picture of heat generation by batteries during normal and extended use conditions which is vital for maximizing safety and performance,” said Gupta.

Rajeev Kumria, general manager, H.E.L India, added, “Poor understanding of battery thermal behavior can lead to unsafe batteries being integrated into devices with inadequate safety precautions in place, and safe batteries being used inefficiently – leading to shortened product lifetimes and poor energy management. As we strive for a more sustainable world, batteries are becoming more prevalent in, for example, electric vehicles and e-scooters, and it is imperative that we continue to research and develop efficient and safe cells appropriate for all environments and applications. As such, we are delighted to be working with IIT Kanpur on this important initiative to help India transition into a more sustainable energy environment, and look forward to providing the latest technology, and sharing our experience in developing battery testing and process safety tools.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.