Researchers at the Centre for Nano and Soft Matter Sciences (CeNS), an autonomous institute of India’s Department of Science and Technology (DST), have developed a ternary composite anode material that exhibits stable cycling performance at high rates and could be a potential alternative to the commercial graphite anode in lithium-ion batteries.

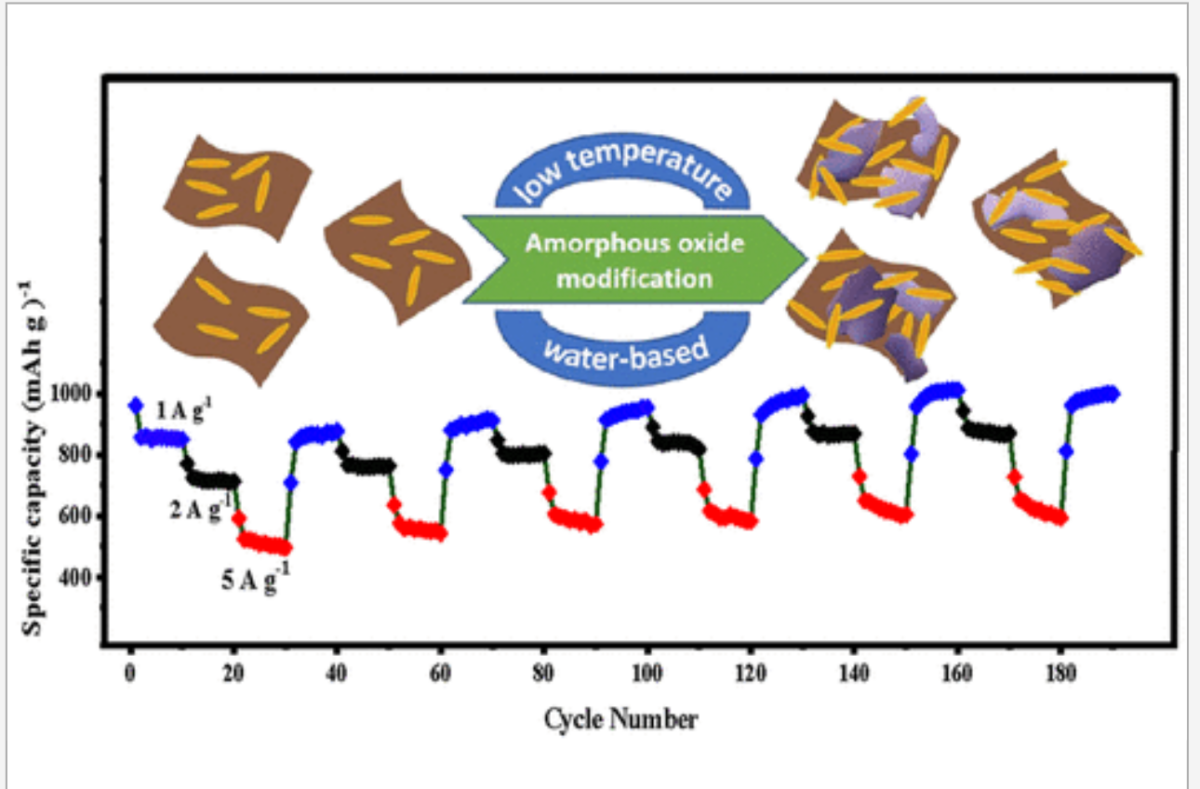

The team, led by H.S.S. Ramakrishna Matte, developed an amorphous manganese dioxide (MnO2)-modified iron oxyhydroxide (FeOOH) ternary composite that addresses the limitations of the bare FeOOH anode arising from poor conductivity and volume expansion. A simple low-temperature synthesis method was employed to obtain a uniform distribution of FeOOH nanorods over the reduced graphene oxide (rGO) matrix, which was further modified with a buffer layer of amorphous MnO2 nanosheets.

The anode exhibited capacities of 956, 842, and 688 mAhg-1 (milliampere-hours per gram mass) after 200 discharge-charge cycles at the rate of 1, 2, and 5 Ag-1, along with cycling stability of 900 mAhg-1 over 100 cycles at 1 Ag-1.

The team used various electrochemical techniques to analyze the superior performance of the ternary composite anode. It deduced that the carbon matrix effectively provides favorable pathways for electron conduction and aids in the stable solid electrolyte interface formation. The amorphous MnO2, on the other hand, maintains the structural integrity of the electrode by controlling volume expansion, which is a major challenge faced by conversion-based anode materials. The exceptional stability of the anode at high rates was attributed to the increased pseudocapacitive nature of the FeOOH-rGO-MnO2 ternary composite anode due to the presence of amorphous MnO2.

“The simple and versatile amorphous-MnO2 modification strategy employed to optimize the FeOOH anode in this work could be extrapolated to other conversion-based materials to address similar problems and achieve their maximum capabilities,” said the researchers.

The research work is published in ACS Applied Energy Materials.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.