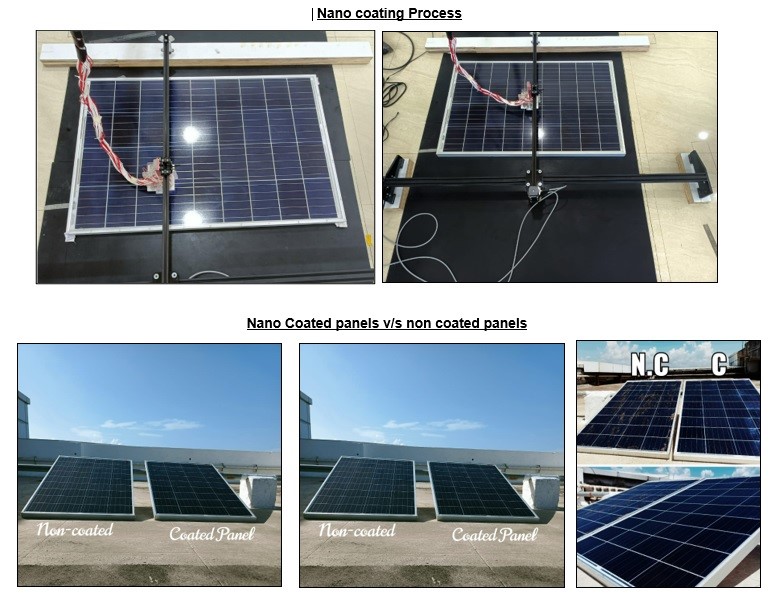

India’s TriNANO Technologies has developed nanocoatings for solar modules that can increase their power output by up to 4% and lower the temperature by up to 3 degrees Celsius compared to non-coated panels.

“This means a 10 MW solar power plant with nanocoated panels would generate additional power of 720 MWh and thus an additional revenue of about INR 17 lakh ($20,737) per year assuming PPA tariff of INR 2.36/kWh,” Harsh Sethi, founder and CEO of TriNANO Technologies, told pv magazine.

The nanocoating is environment-friendly and thermally and chemically stable. It is designed to improve solar panels’ light trapping, anti-reflection, and self-cleaning properties. “Besides increasing the panel’s energy output, these help in anti-soiling and reducing potential-induced degradation (PID). The coating can last for more than five years and reduces panel maintenance and cleaning (especially water-based) costs. Thus, the ROI on our coating can be obtained within about two years,” said Sethi.

Sethi said the nanocoatings were put to extensive testing in several research universities and labs in India and Thailand. The improvements in panel output and temperature were confirmed by the National Center for Photovoltaic Research and Education (NCPRE), IIT Bombay. [NCPRE has a technology and R&D tie-up with USA’s National Renewable Energy Laboratory, Germany’s Fraunhofer, and Australia’s University of New South Wales].

Similar findings were also recorded at the National Institute of Solar Energy (NISE) in Gurugram, and in pilots done at Toyota’s rooftop solar project in Mumbai, a residential rooftop solar plant in Navi Mumbai, and a Tata Power pilot project in Bengaluru.

Sethi said they have applied for the patent on their technology in India and other member countries of the Patent Cooperation Treaty (PCT) and expect it to be granted by 2023.

The coating is done using a portable coating machine and 6 kg frames and can also be applied on existing panels without removing them from service. It is a solid-phase deposition with no liquid involved. On the other hand, the commercially available coatings are made of organic material, are liquid, and applied by paint, brush, or spray method, and therefore they decompose and wither away within two years.

The coating can be applied to monocrystalline, polycrystalline, and thin-film solar panels in ground-mount as well as rooftop applications.

Potential customers are solar panel manufacturers, solar plant owners, and EPC and operation and maintenance contractors.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Please give site details of Navi Mumbai where these panels are installed.

Beats quality

I’m from karnataka mysore

I want nano coating so pls contact 7353238990