From pv magazine Global

Researchers at the Politeknik Negeri Ujung Pandang in Indonesia have proposed the use of vacuum pressure to reduce the operating temperature of PV modules.

“Our vacuum technique is still in the development stage,” researcher Suryanto Suryanto told pv magazine. “but our plan is to bring it to the market at some point.”

The passive cooling method involves a casing to apply negative pressure around the PV module. Negative pressure is pressure that is less than the existing atmospheric pressure and is a condition under which the air pressure is lower in one place in comparison to another.

“If the pressure of a room is lowered, it will cause the room temperature to decrease,” the scientists explained.

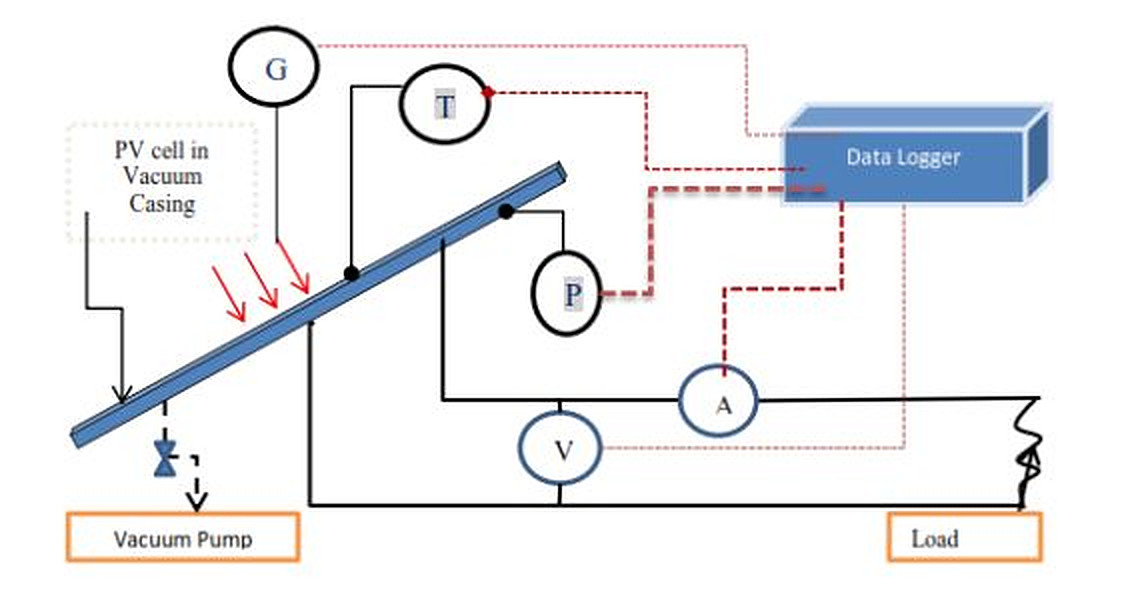

They applied this to a solar module a casing frame made of board material with a thickness of 18 mm. The casing is covered with 5 mm glass – resistant enough to withstand negative pressure. It uses a valve to allow air to be sucked from the casing by a vacuum pump and a pressure sensor to measure the pressure conditions in the PV casing chamber.

The researchers used a temperature sensor to monitor the top and bottom surfaces of the PV module and a temperature logger to collect all data. They compared the performance of the cooled panel with that of a reference module without cooling at an ambient air temperature of around 35 C to 36 C.

They found that the cooled module had a current ranging from 0.89 A to 0.91 A, while the reference module was just 0.62 A. They found that the temperature at the top of the PV panel under vacuum pressure reached a temperature of between 29 C and 30 C, while that of the uncooled module was between 44 C and 45 C. ”

Suryanto said that adding this cooling technique to a PV system could result in an additional cost of $30/kW to $50/kW.

“Regarding plans for mass production we will seriously consider them in the near future, of course with the cooperation of interested industry parties,” he concluded. “A further investigation on the tech costs should be conducted in future work.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.