Metastable Materials, a Bengaluru-based urban mining startup, has opened its R&D and Innovation Center in Bengaluru and plans to double it up as a fully operational metal extraction line by the end of 2022.

Metastable Materials has developed a chemical-free technology that can extract a wide range of valuable materials like copper, aluminum, cobalt, nickel, and lithium from end-of-life lithium-ion batteries in an eco-friendly manner. It claims its patented technology can provide up to 90% recovery of constituent materials for lithium batteries across various cell chemistries.

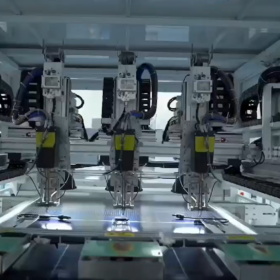

The startup’s newly opened R&D center will carry out equipment fabrication, design and development, and process optimization, among other strategic areas for the company. The 5,000-sq.ft facility is equipped with state-of-the-art infrastructure and equipment, including an in-house quality analysis lab to perform regular quality checks of the extracted materials and a parallel focus on continuous improvements in process efficiency and yield.

Metastable aims to ramp up the facility to run at its full capacity by the end of the current fiscal 2022-23 and bolster commercialization optimally for the company. The plan includes doubling up the facility to function as a metal extraction line by the end of 2022 – with the capacity to handle the processing of up to 600 tons of end-of-life Lithium-ion batteries per year and eventually cater to 4 to 6% of India’s end-of-life Li-ion batteries treatment value chain.

At the facility, Metastable’s process engineering team will conduct regular experiments to increase efficiency, yield, and purity of the various output materials obtained through Metastable’s patented technology.

“Majority of the metals extracted from Li-ion batteries have an overall trade deficit. These are currently facing a supply crunch in the domestic market and are being imported from other countries at higher prices. We foresee a huge opportunity for …offering these commodities at a lower price than the market,” said Shubham Vishvakarma, founder and head of process engineering, Metastable Materials.

“Our newly-inaugurated facility will play a pivotal role in enabling that and giving impetus to a circular economy. Once technology validation is proven at scale at this facility, Metastable Materials plans to develop India’s urban mining infrastructure based on its new and improved processes over the next two years or so.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.