From pv magazine Global

Swiss solar module manufacturer Megasol has launched the bifacial module M500-HC-144-b RC GG U30b with a reported power conversion efficiency of 23.2%.

The company claimed to have improved the efficiency of the panel, which previously featured an efficiency of 22.1%, through a new back-contact technology dubbed “RearCon.”

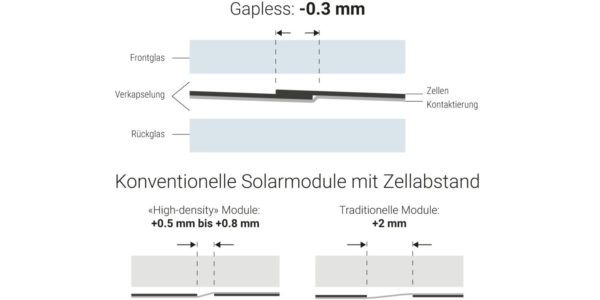

“By moving the busbars to the rear, we eliminated the problem of self-shading, as every contact on a cell covers cell area with which electricity can be generated,” explained Michael Reist, head of communications and marketing at Megasol. In addition, the manufacturer said it used busbars with particularly high conductivity for the rear contact. “This reduces the internal resistance and, as a result, the ohmic losses considerably,” Reist continued, noting that this also reduces the cell spacing. “In fact, the cell spacing is negative — the cells overlap very slightly by 0.3 millimeters. This gapless stringing leads to space savings and higher efficiency,” he affirmed.

The rated output of the new 144-cell glass-glass module is 500 W. Depending on the albedo of the ground, a bifacial additional yield of up to 30% is possible, according to the product sheet from the Swiss photovoltaic manufacturer.

Image: Megasol

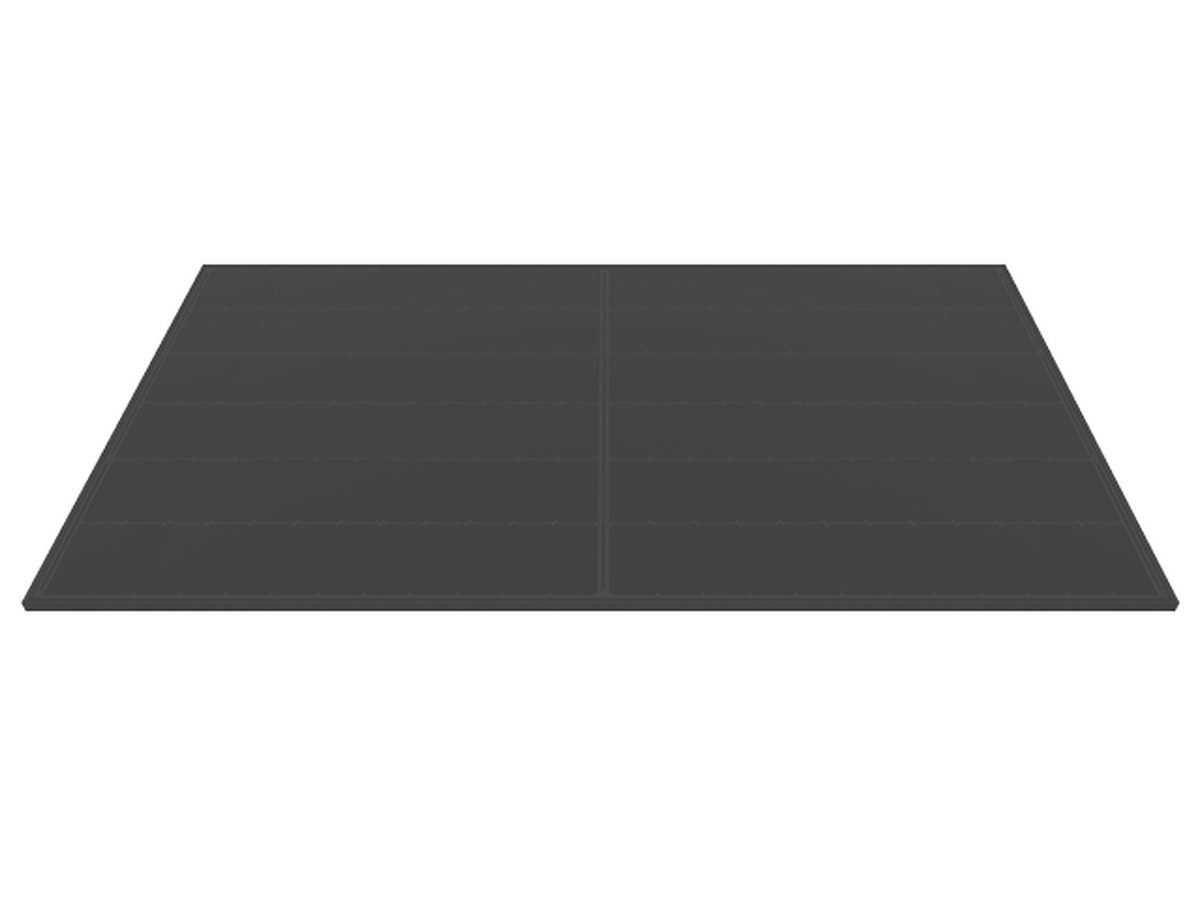

The dimensions of the module are 2,063 x 1,046 x 30 mm and its weight is 26.5 kg. It features a black anodized aluminum frame and is suitable for use in a temperature range of -40 to +85 degrees Celsius and a maximum system voltage of 1,500 volts. The manufacturer offers a 15-year product and 30-year linear performance guarantee for its new module.

“The RearCon technology requires only about half as many production steps as the production of previously known solar modules with rear contact,” Reist further explained. Which production steps would be saved is a trade secret. However, the cheaper production will affect the overall costs for customers. “We would like to pass this cost advantage on to our partners. That’s why the prices of the RearCon solar modules are significantly lower than what has previously been seen for solar modules with rear contact. That can be 30% or even more,” he added.

Megasol sees significant improvements not only in terms of performance and production costs, but also in terms of appearance, since it is a completely black module. “The contacts on the back of the busbars result in a more homogeneous appearance and thus significantly improved aesthetics of the solar modules,” the manufacturer said. “This is particularly important for use in solar facades.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.