The Indian government has been trying extremely hard to build a local manufacturing base for solar modules in India. First, we tried to boost the local assembly of modules with the Jawaharlal Nehru National Solar Mission scheme. However, we faced trial in World Trade Organization (WTO) and subsequently lost the case.

Later, India introduced new measures in 2018, including safeguard duty on imports of PV cells and modules, mandatory BIS certification and registration of cell and module companies with the Ministry of New and Renewable Energy (MNRE). However, these measures failed to arrest the growth of imports in India.

Moreover, the imposition of safeguard duty slowed India’s capacity addition and increased prices for utility-scale projects by 15-20 paise, making rooftop projects more capital intensive.

From August 2020, customs duty is expected to be imposed on modules, cells, and maybe on wafers and ingots. This is another attempt by the Indian government to arrest Chinese imports. However, these attempts are unlikely to yield the desired results of ‘Make in India.’

Assemble in India

The majority of Indian manufacturers are unable to compete on the pricing and quality offered by their Chinese counterparts. Apart from a few GW scale companies, most manufacturers have capacities in 50-200 MW range.

The fragmented nature of Indian manufacturing does not offer any economies of scale, making modules costlier. Thus, manufacturers are unable to invest in the upgradation of their technology.

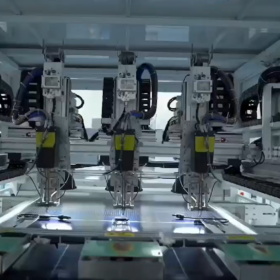

The Chinese have deep vertical integration of the supply chain, straight from making of ingots, wafers to cells, and modules. This reduces their production cost and gives them better control over the pricing.

On the contrary, India does not have any local manufacturing of ingots and wafers and is dependent on China for the same. Ingots and wafers are required to produce the silicon cells that go into the modules.

India has a silicon cell manufacturing capacity of about 3.1 GW (split between 18 companies) and module capacity of 11 GW (consisting of 175 companies). This simple figure of 11 GW of modules and 3.1 GW of silicon cell manufacturing is enough to say that even at 100% production levels, Indian silicon cell manufacturing capacity can meet only 28% of the demand.

Hence, most of the module manufacturers are assemblers heavily dependent on the import of solar cells to assemble the modules in India.

Before taking any action on the subject of Chinese imports, the policymakers must consider that China controls the supply chain for cell manufacturing in India. In the absence of a local manufacturing base, India relies on imports of ingots and wafers to make the silicon cells. Since our local silicon cell manufacturing capacity is insufficient to meet our demands, Indian modules will continue to use imported cells.

Hence, without a comprehensive policy to focus on building a vertically integrated supply chain, isn’t the entire concept of ‘Make in India’ a pipedream?

In January this year, the Solar Energy Corporation of India (SECI) successfully concluded a manufacturing-linked tender for the development of new factories to manufacture 3 GW of cells and modules. It linked the installation of 12 GW of utility-scale projects with modules produced in these new factories.

The winning price in the auction was Rs 2.92 per kWh, which is about 42 paise higher than SECI’s auction of 1.2 GW of ISTS linked projects in February 2020.

These manufacturing capacities are expected to be met in 2022, and installations will begin after that until 2025.

It is a well-accepted fact that module prices have continued to fall, and there has been a massive improvement in cell efficiency and other technology parameters for solar modules. So, today’s 42 paise higher cost might turn out to be more than Re 1 by 2025.

This raises the cost of power for the end consumer, many of which are industries. Wouldn’t this work against ‘Make in India’ for industries that are not in the solar business? Lastly, this manufacturing linked tender still does not address the lack of ingots and wafer building capacity in the country.

To sum up

India relies heavily on Chinese imports of silicon cells, ingots, and wafers to ‘assemble’ the modules in India. Though “Make in India” is a thought that should prevail, we cannot achieve this by banning Chinese imports.

Our entire solar industry is dependent on Chinese imports to function. Hence, there is a comprehensive need to relook at the current policies and focus on building wafers and ingots capacity that will be used to manufacture the cells and eventually, modules. Such a policy will take time to draft and maybe 4-5 years to show results. Until then, if we decide to ban or impose high duties on Chinese imports, it will result in an exorbitant increase in the prices of solar modules or a shortage of them.

Given that modules constitute 60% of a solar PV project cost, we might see project costs escalated anywhere from 10-25%, depending on the quantum of the duty imposed. At such escalation, we will effectively vaporize the demand for rooftop solar in the country.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

China today is due to efforts taken by their government 20 years back. Today Government led by Modi is supporting Indian manufacturers to create in India , increase jobs for our local people and not just import from China just because it is few dollars cheaper.

Consider the cost in terms of lives of our soldiers who lost their lives during recent border skirmishes.

A consortium of companies must invest in the supply chain support one another in a joint to keep the solar industry from ingot to cells to maintain dependent down stream MSME’s to maintain the targets laid out in the next 5yrs .This must be supported by government as a strategic investment for next 10 years.

Is making Solar Grade Ingots and Wafers really…. “Space Age Technology” that India needs a “begging bowl” to get them from…. unfortunately China… as India and others enforce a PEOPLES BOYCOTT OF CHINESE GOODS & SERVICES….???

This reminds me of 1950/60’s when under Nehru…. India country was always begging…. for food… around the Globe. Nehru died in 1964…. next PM was Lal Bahadur who suggested “miss a meal/week” leading from the front (like PM Modi did for Swatch Bharat…. Clean India… with a Broom)… the rest is history….

In his brief (<2years) service to the nation, as Prime Minister, he launched The White & Green Revolutions…. and converted India from a Land of Perpetual Milk and Food Shortage to Self-Sufficiency in BOTH….

BOTH were also achieved by the Farmers of India … and NOT it's Industry.

Perhaps, India needs to re-look its strategy in expecting "The Industrial Complex of India" to walk "upto the wicket" and hit those much needed " Runs, Boundaries & Sixers" … for its Ingot, Wafer & PV Cell and Power Industry as the nation aligns itself with the ZERO POLLUTION OPTION(s) of The Green Deal(s) in Europe, US and elsewhere.

Here…. GW/GWhr Ambitions will have to be replaced by TW/TWhr ones…. but is Indian Industry listening…!!!!

Unbelievable article. This kind of creepy thinking that all he’ll breaks loose if Chinese imports are stopped is what China is banking on. So we stop plant setup till we localize or buy elsewhere. This uninspiring article which bemoans the author and his ilk talks of failure where open opportunity has opened. Buying from China is no option, u useless industry man. It is not some brahma video to make solar panels. Over many years in manufacturing we have beaten back Chinese producers. Indian suppliers have given cheaper, better quality and ease of supply of variety of items. Just do it. No china, forever