pv magazine: Proper scheduling and forecasting significantly influence the financial returns on a PV plant. What does Solar-Log offer regarding this?

Silvia Blumenschein: We offer knowledge transfer to customers, with Site Maintenance (SM), Preventive Maintenance (PM) and Corrective Maintenance (CM) helping to reduce failure rates. Mostly, we evaluate a PV plant’s performance based on actual energy produced from the sunlight falling on the array, compared to the expected. System design, performance drops, force majeure events, breakdowns and degradation ratios, on the event of before and after scheduled activities are taken into consideration. This helps us to more accurately forecast what is needed, depending upon geographical location, along with the knowledge base we have built over the last decade.

With our industrial experience and expertise, we define what site activities are needed as per geographical location. Also, we can track what is, and is not, done, at what time. We even do an in-depth drill-down analysis to correlate failures, due to improper scheduling and forecasting, along with component-specific revenue loss. This will help our customers define key performance indicators (KPI’s) and have a deeper insight into EPC and O&M contracts.

How accurate is the forecasting of the PV generation? Which methodology do you apply?

We use virtual irradiance to calculate generation forecasts. Also, we recommend that our customers provide us with an Independent engineer (IE) report, which has the energy forecast and irradiance data. With this, we use a Weather Performance Ratio (WPR) to identify the deviation with the actual data where the weather stations are being installed. However, we have determined that hourly forecasted weather data has a 20% deviation from actual sensor readings – and when you compare it to 24 hours, the deviation is 8 to 10%. We are in talks with multiple meteorological solar irradiance software providers to see if they can reduce the deviation to 5%, so that energy forecasting can be done more efficiently.

How effective is remote monitoring in reducing the failures of a PV plant?

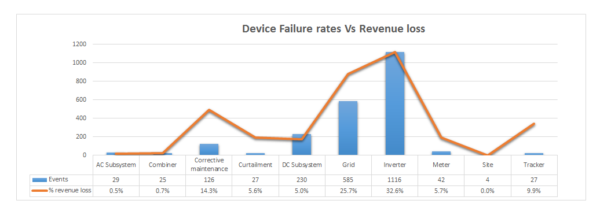

With continuous plant data availability and a good ticketing history with the Solar-Log software as an example, the data analytics team can analyze project performance based on numerous factors, like system impact due to failures in equipment, and components associated along with an estimated energy loss and revenue loss as per power purchase agreements (PPA). We did a case study with a sample of 100 PV projects in our fleet during this year, where we could identify the actual failure areas with a possible root-cause for those system outages, and the number of events associated with revenue losses.

With this data, we also conducted a prediction fault analysis with forecast failure rates, like for example, how many are related to components, devices, and/or are site-specific. Based on this, we can work on the KPI’s of EPC’s and O&M.

Asset Management is one of the key features, Solar-Log offers. How do you assess, since every plant is different, depending on location, components and quality?

We have globalized standard methods to evaluate the performance of assets, irrespective of their location, or the components or technology used. Let’s say we have a 1MW PV plant built in the APAC and EMEA region. We follow one unique method, which defines the performance of the plant.

With over 10 years of industrial data, we evaluated many systems and formed a globalized methodology in assessing performance. We also provide our customers with a standard metric or customer specific metric to evaluate their site yields. If a project has been completed and is in the handover phase, we evaluate the system through the Facility Acceptance Test (FAT) and Site Acceptance Inspection (SAI). Is the performance is being met as per the guarantees? This we evaluate through standard defined metrics with a clear HOTO (Handover/Takeover) process.

Tell us about your monitoring device/data logger, which was introduced at REI 2017?

We have come up with a new product, which is defined as a gateway product. As a first step, we to tend to match it with Indian solar market’s requirements, specifically for smaller systems (max. 30 kW), particularly designed for small plant capacities. As a second step, we will approach commercial sites up to 250 kW. Our vision is to offer a portfolio with basic, general and numerous features at different pricing levels, so that all solar plants installed have the potential to install a monitoring system. It is all about the protection of the PV investment, financially, technically and commercially.

Will this new product, Solar-Log Gateway, also be compatible with all inverters and other, associated components on the market?

As the market is growing rapidly, there is an emergence of innovations and new technologies and, because of that, many inverter brands crop up. Every day is a new learning curve and growing experience, also for us at Solar-Log. We carefully study the market potential of each inverter brand and its associated models; we do a benchmark on how the integration support will meet the demands of the customer concerning sales. As of now, we have integrated more than 100 different inverter manufacturers covering more than 1800 inverter models, and still counting. When it comes to components, we are also compatible with meters, heat pumps, charging stations for electric vehicles, and battery storage systems.

Some inverter suppliers already have inbuilt monitoring systems. How do you compete with them?

We do not compete with them. We are neutral and inverter independent; our approach is a different one. Most of the inverter manufacturers’ front-end software provides real-time information, but in many cases, they do not log all the events, alarms and other maintenance issues. In such cases, there is very little documentation that can help O&M personnel to identify, diagnose and trace problems. Solar-Log provides a value-added service called Solar-Log WEB-4U, with a dedicated support team where PV plants are being monitored very closely on all available component levels. Failures are detected with minimum downtime and reported to the field service team, followed by a brief explanation of the failure. Pinpointing the device failure, along with the part that failed would help the field tech to carry the exact spare, which is required to fix the issue with minimum time.

In this respect, we also support the various manufacturers in identifying failure rates on each component. The kind of faults with their occurrences would also help them to identify a solution.

What is Solar-Log doing for module or string level monitoring?

If we are compatible with an inverter that has string monitoring, then we plan to provide string-wise specific yield with the actual irradiance, which would be the optimized solution. For the ones that do not have string level monitoring, we plan to integrate with SMB’s and SCB’s, which has wide market potential and also the ones which provide maximized solutions meeting customer demands. We are currently more focusing on competitive data logger for Indian market requirements.

What is your strategy for the Indian market, which is growing at a tremendous rate?

We are among the data loggers and monitoring systems in the market meeting SECI’s (Solar Energy Corporation of India’s) current requirements; and we are working on their future requirements. We have an office and warehouse in Navi Mumbai; and we have a two-pronged approach for the new growing market in India where we are closely working on having distributed channel partners across multiple regions in India for our further business expansion. Our in-house sales team will maintain and manage key accounts. Also, we have an integration team for the new market-specific requirements, followed by a dedicated technical support team for commissioning and managing the solar plants 24/7 globally.

Indian climate is more tropical than many other parts of the world. What does Solar-Log offer to Indian customers (EPCs, project developers, etc.) ?

With more than 10 years of industrial data and with our multi-geographical experience, we recommend to our clients what the do’s and don’ts are. We offer site-specific information, for example, soilage (soiling on solar panels), structural impacts and correlation factors of temperature increases subject to energy drops. Also, we will soon add capacity utilization factor (CUF) and device availability factors for all PV plants provided with few additional functionalities as per market needs, which will help to build an excellent asset management platform.

How many systems are you monitoring in India? What are your next targets including India?

We have a global installed capacity close to 11.9GW across 272,000. In India, we have close to 2,500 functioning loggers, with over 350MW at work already. We plan to support 1GW in the upcoming two years.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.