Jakson to set up high-tech solar PV module recycling line in partnership with Europe’s Ecoprogetti

Jakson Engineers Ltd will set up a high-tech solar PV module recycling plant capable of recycling around 5,00,000 PV modules, or approximately 13,500 tonnes of modules per year, recovering critical materials and enabling responsible end-of-life solar management. The recycling line will be supplied by Ecoprogetti.

From waste to resource: Recovering critical minerals for solar and EV batteries

As India ramps up solar installations and EV deployments, the volume of end-of-life components will grow rapidly. If these are treated simply as waste, we create new environmental burdens and miss a chance to recover value. If, instead, they are viewed as sources of supply, they become part of the solution.

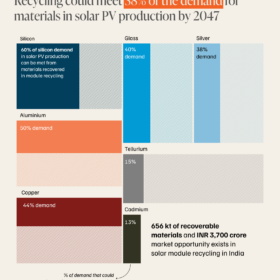

Solar module recycling offers an INR 3,709 crore market opportunity in 2047: CEEW

India is estimated to generate over 11 million tonnes of solar waste by 2047. Recycling could meet up to 38% of India’s future solar material needs.

PV module recycling gains momentum as waste volumes surge globally

A comprehensive new report from IEA PVPS Task 12 reveals how countries around the world are managing the growing volumes of end-of-life solar modules, implementing regulations and scaling recycling infrastructure to handle the expected increment in PV waste over the coming decades.

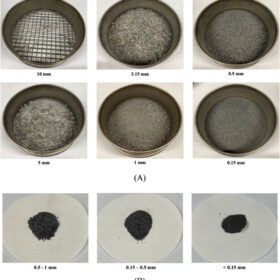

New sieving tech for solar cell silver recovery

Researchers at University of New South Wales have reported details about a novel sieving-aids technology that improves the separation of metal fragments from other components when recycling end-of-life PV panels. The patented process reportedly enhances the recovery of silver.

MIT-WPU researchers develop scalable solar PV waste recycling process

Researchers at MIT World Peace University (MIT-WPU) have developed an innovative process that not only enables recovery of valuable materials from end-of-life solar panels but also upcycles non-recoverable fractions into construction materials such as bricks, blocks, and aggregates. This dual approach prevents hazardous waste from entering landfills while reducing dependence on virgin raw materials.

Solar myths and misconceptions put to sword

In a new monthly column for pv magazine, the International Solar Energy Society debunks old and new urban legends about solar energy.

Solar panel recycling plan urges repair, reuse first

Australia’s rooftop solar industry has renewed calls for a mandatory recycling scheme to deal with the growing problem of solar panel waste. Only about 10% of panels are currently recycled. The rest are stockpiled, sent overseas or dumped in landfill.

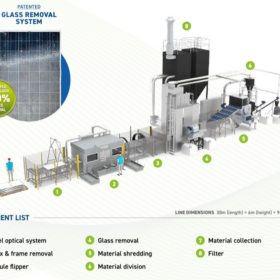

Ecoprogetti releases fully automated solar panel recycling line

Italy’s Ecoprogetti has developed an automated photovoltaic recycling line that separates and recovers up to 100% of the aluminum, copper, glass, plastic and silicon in solar panels. It can process up to 60 panels per hour while using 40% less energy than other solutions on the market.

Germany has urgent need to expand solar module recycling capacities, IEA-PVPS says

Feedback from stakeholders involved in Germany’s end-of-life PV modules treatment chain found more needs to be done around the transparency of PV module waste volume, the take-back and collection process and module recycling, as the country prepares for significantly larger volumes by the end of the decade.