Solar power on the rise: A buying spree fuelled by innovation and price wars

While companies grapple with razor-thin margins, these price wars are accelerating the adoption of solar power globally.

Solar industry grapples with oversupply and uncertainty

The solar industry stands at a critical juncture. Oversupply, regulatory hurdles, and technological advancements are all reshaping the landscape. Manufacturers must adapt swiftly, balancing production with demand while navigating the complexities of global trade.

‘In the next year, some of these guys are going to be bankrupt’

At Intersolar in Munich, pv magazine spoke with Jenny Chase, solar analyst at BloombergNEF, about the incredibly low polysilicon prices, massive overcapacity, and increasing consolidation. According to Chase, this year there will be enough polysilicon capacity to produce 1.1 TW of solar modules, but global module demand is expected to reach around 585 GW. “That is a pretty huge delta,” she said, noting that the solar industry should also prepare for a series of “negative feedback mechanisms,” such as negative prices and excess of solar power.

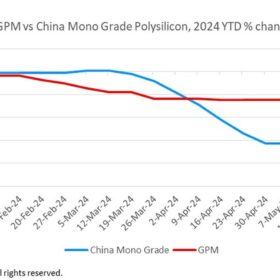

Polysilicon prices stable, market concerns persist over worst-case scenario

In a new weekly update for pv magazine, OPIS, a Dow Jones company, provides a quick look at the main price trends in the global PV industry.

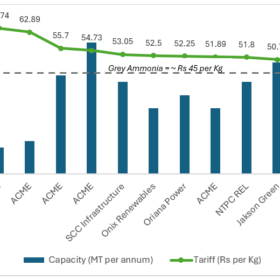

Polysilicon price plunge sparks industry turmoil: Can India gain?

Lower polysilicon and wafer prices are providing some relief to solar cell and module producers, although the entire supply chain is grappling with excess capacity and intense price competition.

Reliance completes sale of REC’s polysilicon manufacturing unit

Reliance Industries Ltd (RIL) has completed sale of REC Solar Holdings’ kerf-based polysilicon manufacturing arm, REC Solar Norway, to Elkem ASA. It continues to retain the technology and intellectual property rights of kerf-based polysilicon post sale of REC Solar Norway.

Trina Solar records 65.21 GW of solar panel shipments for 2023

Trina Solar says its solar panel shipments reached 65.21 GW in 2023. The Chinese module maker achieved a turnover of $15.75 billion and a net profit of $768.2 million in fiscal 2023, with an annual module production capacity of 95 GW by the end of December.

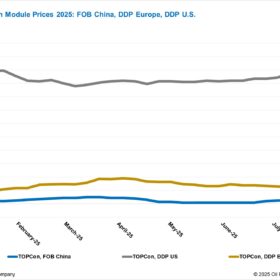

Solar bloodbath: Titans clash in ruthless price war

The ongoing price war between top global suppliers could catalyse more competitive solar panel pricing in the Indian market, potentially leading to an increase in solar adoption at both the commercial and residential levels.

OCI increases production capacity at Malaysian polysilicon factory

OCI has revealed plans to invest $617.9 million to expand production at its Malaysian manufacturing facility from 35,000 to 56,600 metric tons.

How much polysilicon is enough

TU Delft researchers have proposed a new approach for solar cell manufacturing that implies gauging wafer thickness depending on the regions where the cells and modules will be deployed. They also suggested to adopt test conditions that are representative of the outdoor working condition of solar cells in an alternative to standard testing conditions.