World’s first transnational solar power grid network launched in Glasgow

The India and UK-led global supergrid program seeks to connect 140 countries to round-the-clock green and renewable power.

Zinc-bromide battery for stationary energy storage from Australia

Australian startup Gelion is seeking to commercialize a non-flow zinc-bromide battery based on a stable gel replacing a flowing electrolyte. According to the manufacturer, the device is safe, robust and recyclable.

Solliance hits 29.2% efficiency on perovskite/silicon tandem solar cell

The Solliance consortium has built a solar cell in a four-terminal tandem configuration that combines a 17.8%-efficient highly near-infrared transparent perovskite cell with a prototype of an 11.4%-efficient c-Si interdigitated back contact silicon heterojunction cell developed by Panasonic.

Should I include a battery with my home solar project?

An increasing share of residential solar arrays now include energy storage batteries. In this article, costs, benefits and timing of these batteries are evaluated.

Sunman unveils 430 W glass free solar module

The new product has a power conversion efficiency of up to 19.3% and a weight of 11.2 kg. The module is produced with glass fiber reinforced plastic, which the manufacturer says reduces light reflection and opens up new assembly options.

Compressed-air storage for commercial applications

Israel-based Augwind has built its first 250 kW/1 MWh compressed air storage system for the collective community of Yahel, in the southern, desert part of the country. The commercial scale facility will be connected to a PV system and will be used for behind-the-meter services.

Hydrogen power generator for isolated areas, construction sites, events

Developed by French start-up EODev, the 100 kVa system is equipped with fuel cells manufactured by Toyota. The generator has a power of 110 kVA and its lifetime is guaranteed for 15,000 hours.

Solar job numbers kept on rising in 2020

The latest edition of a clean power jobs survey produced by IRENA and the International Labour Organization has stressed the important role which will need to be played by the public sector if the energy transition’s employment benefits are to be shared equally.

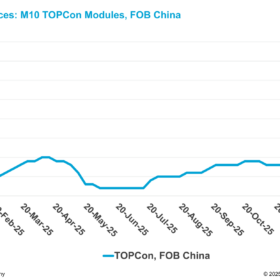

Module and shipping cost inflation could cost the world 50 GW of solar next year

The input costs of the two biggest contributors to solar plant development expense have gone through the roof since the world began to come out of Covid-19 lockdowns, to leave project developers with some difficult choices.

Australian prefabricated solar array manufacturer launches new modular solution

Sydney-based 5B has taken the wraps off a new generation of its re-deployable modular Maverick solar technology which it says is not only quicker and easier to install than the previous model but 30% more powerful.