Rooftop solar price to keep rising this year

British analyst GlobalData has predicted residential and commercial rooftop panels will not return to a declining price trend until next year, with post-Covid logistics headaches the cause, rather than a polysilicon shortage.

Soluna unveils 1.28 kWh portable power generator

Soluna’s new generator can be combined in a two-unit system to reach a capacity of 2.5kWh. It features built-in 120V(AC) output, continuous AC output power of 1,200W, and peak output of up to 2,400W.

Solar power prices rising with demand

Recent BloombergNEF research shows that corporations procured a record 31GW of renewable energy in 2021, and LevelTen Energy says that growth occurred despite more than a year of price increases.

Water-based electrolyzer for green hydrogen production

Verdagy has secured a $25 million investment for its new electrolyzer technology, which provides hydrogen fuel for heavy industrial applications. The membrane-based technology uses large active area cells, high current densities, and broad operating ranges to deliver hydrogen at scale.

New poly fabs could head off first-half solar project slowdown

Norwegian analyst Rystad Energy has warned the solar industry could suffer the same effects of rising input prices as onshore wind developers grappling with ever more costly steel, with much hinging on how much solar panel raw material polysilicon can be manufactured.

Residential based energy storage will become the new ‘Boiler 2.0

Residential-based energy storage will become the new ‘Boiler 2.0’ and could form part of a virtual power plant, providing a viable solution to the global energy crisis and helping us to achieve our net-zero goals.

New agrivoltaic system design from Germany

Germany’s Sunfarming is testing the new project design in cooperation with research centers Jülich and the Fraunhofer ISE.

The long read: Is the coast clear for solar to head offshore?

There are literal oceans of space for floating PV (FPV), beyond the first applications on lakes, reservoirs and hydro-electric dams. For countries where land is at a premium, such as the Netherlands, Singapore, and Japan, offshore FPV is of particular interest. Of course, unlike a reservoir, the sea is rarely still. Thankfully FPV’s growth has also brought technological innovation and maturity with it, meaning the coast could now be clear for solar to head offshore.

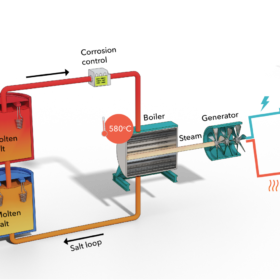

Storing solar power with grid-scale molten hydroxide

Seaborg Technologies, a Danish manufacturer of molten salt nuclear reactors, has turned a technology that was originally developed for nuclear power into a large-scale storage solution for wind and solar. It has developed a storage system that uses renewable energy to heat salt with electrical heaters, based on two-tank molten salt storage designs developed for concentrated solar power plants.

‘Solar and wind deployment could not now be stopped if we wanted to’

BloombergNEF’s Jenny Chase has surveyed the state of affairs in world solar for clean energy journal Joule and said the technology’s historic ability to surmount obstacles – and persistently confound analysts’ predictions – should offer a reason for hope.