Why do solar power plants work inefficiently?

When choosing a solar power plant, individuals and businesses pay the most attention to its power – after all, this will determine how much electricity will be produced. Other equipment, systems and sensors that allow monitoring and analysis of the operation of the power plant are often underestimated. But they shouldn’t be: the solar power plant will be used for several decades, so various failures and poor-quality monitoring can have a significant impact on the efficiency of electricity production.

Husk Power Systems secures $6 million from EU-funded EDFI ElectriFI

Bihar-based Husk Power Systems will use $6 million of newly acquired funds to build solar hybrid microgrids in 80 communities in rural India. The renewables services provider already owns and operates more than 120 microgrids in India.

Airtouch Solar to supply solar-cleaning bots in India

Israel-based Airtouch Solar has signed a $940,000 contract with Indian developer Hero Future Energies, three weeks after securing a $440,000 project with another developer in India.

Handheld tool to clean rooftop solar panels

Mumbai-based Cleo Tech has developed a battery-powered, handheld tool for scratch-free, dry cleaning of solar panels. The tool’s cleaning brush clings end-to-end on the aluminum frames of the panels, avoiding direct contact of the moving parts with the cells, other than the soft nylon bristles.

Pure solid state batteries from Switzerland

Swiss Clean Battery is set to start commercial production of its pure solid state batteries in Switzerland. The batteries are based on a protected electrolyte made of a solid ion conductor, which helps to maintain internal resistance and capacity. The fixed ion conductor is formed in the battery cell itself, similar to a multi-component adhesive.

Tractor-mounted, hydraulic panel cleaning arm for solar farms

Tamil Nadu based Next Automation has come up with a tractor-mounted hydraulically operated arm as a fast, accurate, cost-effective, and water-efficient cleaning solution for panels in solar farms.

Ecoppia’s full robotic cleaning suite lands job at Azure Power’s 400MW solar site

The Israeli robotic cleaning specialist will deploy its E4, T4 as well as the latest H4 products for the Indian developer’s 400 MW solar project that combines fixed-tilt and single-axis trackers.

Water-free, portable cleaning bot for rooftop solar

India’s Aegeus Technologies has developed an autonomous, water-free cleaning bot for rooftop solar installations. The bot weighs 5 kg (with battery) and can be operated remotely through a web-based app. It uses an air wash technology to clean the panels, ensuring no need for water or any harmful chemicals.

Compressed air tech for solar module cleaning, cooling shows promise in India field-testing

British scientists have reported significant restoration of the panel performance with the experimental compressed air system developed by them for the simultaneous cleaning and cooling of PV modules. The system was built with a compressed-air unit which was made of a compressor, an air tank, and an airflow regulation valve, and a series of nozzles. The technique was tested on a PV system located in northwestern India.

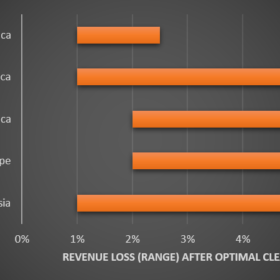

New model to predict PV module cleaning cycles and resulting profits

A group of scientists in Bangladesh has developed a model to determine the optimal cleaning schedule for a PV installation at any location in the globe, requiring only the average insolation and soiling rate for a given site to make the calculation. The study also draws new conclusions regarding the influence of sandstorms and rain on soiling, and aims to be among the first studies to paint a global picture of soiling trends by region.