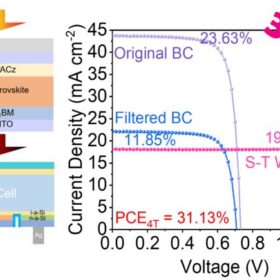

Chinese scientists build 31.13%-efficient perovskite-silicon tandem solar cell via 2D seeding agent

Researchers in China developed a novel two dimensional (2D) seeding agent to regulate crystallization in a 1.80-eV wide-bandgap perovskite film. A perovskite-silicon tandem device made with the resulting optimized subcell achieved an efficiency of 31.13%, outperforming a control device.

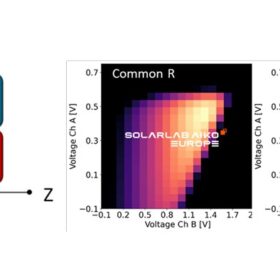

Aiko achieves 34.76% efficiency for 2-terminal perovskite-silicon tandem solar cell

The Chinese manufacturer said its 2-terminal 34.76%-efficient perovskite-silicon tandem lab-scale cell is based on heterojunction technology and developed by a collaboration of Solarlab Aiko Europe, Aiko headquarters, and its R&D in Yuwi, China.

NTU achieves high stability in 25.1%-efficient inverted perovskite solar cell

Researchers at Nanyang Technological University have demonstrated a method to integrate chemically inert low-dimensional interface materials into the fabrication of inverted perovskite solar cells. Their prototype solar cells retained over 93% of the initial power conversion efficiency of 25.1% after 1,000 hours of operation, and 98% after 1,100 hours at 85 C.

Japan launches R&D call for tandem perovskite solar cell mass production

Japan’s New Energy and Industrial Technology Development Organization (NEDO) is accepting proposals for a six-year R&D program to advance large-scale manufacturing technologies and field testing of next-generation tandem perovskite solar cells.

KAUST achieves 28.7% efficiency in perovskite-perovskite-silicon tandem solar cell

An international team of researchers led by King Abdullah University of Science and Technology has fabricated a triple junction perovskite-perovskite-silicon tandem solar cell that achieved a world record efficiency for this cell architecture. The device incorporates stabilized perovskites that ensure improved performance and stability.

Scaling perovskite tandems’ U.S. prospects

Three US manufacturers actively working to commercialize their respective perovskite-silicon tandem technologies make the case for tandem modules. CubicPV, Caelux and Swift Solar argue a commercial future for perovskites is inevitable, and they tell pv magazine the current policy environment could work in the technology’s favor.

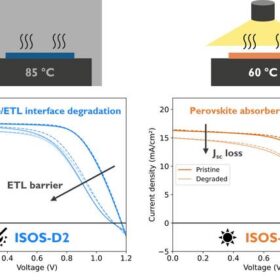

Researchers identify main source of wide-bandgap solar perovskite degradation

Scientists in Belgium have investigated how perovskite absorbers used in solar cell degrade under three different stress test types and have found that the interface between the perovskite layer and the electron transport layer suffers from weak thermomechanical stability, which creates the conditions for performance losses.

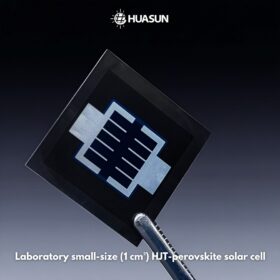

Huasun achieves 34.02% efficiency for perovskite-heterojunction solar cell

The Chinese manufacturer said the result was achieved thanks to new perovskite crystallization additives and high-mobility carrier transport layer materials.

Renshine Solar hits 27.5% efficiency for flexible all-perovskite solar cell

Renshine Solar says it has achieved a record 27.5% efficiency for a flexible all-perovskite cell and 23.0% on a 20.26 cm² panel.

Inside perovskite solar cell durability and performance testing

Accurately measuring the performance of perovskite solar cells and modules requires significant modifications to long-established testing standards used in silicon PV. Researchers are settling on methods that rely on up to several minutes of constant light exposure and other time-consuming procedures. These may be fine for the laboratory setting, but those looking to produce this technology at scale need standardized methods that can characterize cells and modules at a much faster rate.