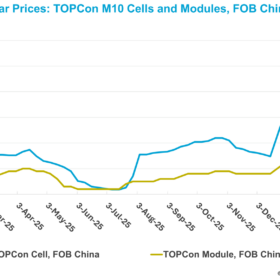

Solar industry grapples with oversupply and uncertainty

The solar industry stands at a critical juncture. Oversupply, regulatory hurdles, and technological advancements are all reshaping the landscape. Manufacturers must adapt swiftly, balancing production with demand while navigating the complexities of global trade.

Lifecycle management in renewable energy projects

Routine inspections, monitoring systems, and predictive maintenance techniques play a vital role in optimizing energy output and ensuring the success and longevity of solar and wind power projects.

BirdBlocker unveils bird-proofing solutions for rooftop PV at Intersolar

Dutch company offering bird-proofing solution for solar installations expands its range with a trio of launches – with high hopes that its business can take flight on commercial rooftops.

Israeli startup launches agrivoltaic pilot in desert with double-axis sun tracking

Agri-Light has launched its first pilot agrivoltaic project, using a two-axis solar installation on a rail system to move solar panels horizontally above a vineyard in the Negev Desert. The results are due this summer, and the company plans to build commercial projects in Israel and Spain next year.

IEA-PVPS releases fact sheet on environmental life cycle assessment of PV Systems

The updated IEA PVPS Task 12 Fact Sheet provides a comprehensive assessment of the environmental impacts associated with PV systems. It highlights the significant advancements made in PV technology, emphasizing improved efficiencies and reduced environmental footprints.

SJVN inks renewable power supply MoU with AM Ammonia

SJVN Green Energy Ltd has signed a Memorandum of Understanding (MoU) with AM Green Ammonia (India) for long-term supply of renewable energy to AM Green’s forthcoming green ammonia plants in Andhra Pradesh.

The Hydrogen Stream: Hygenco secures green ammonia offtake agreement with Ameropa

India’s Hygenco Green Energies has signed a term sheet with Switzerland’s Ameropa for the potential supply of green ammonia from its forthcoming project at the Gopalpur port in Odisha.

Amara Raja signs LFP battery technology deal with China’s Gotion

Amara Raja Energy & Mobility Ltd has secured the technology license from China’s Gotion High-Tech to manufacture lithium ferro phosphate (LFP) battery cells in both cylindrical and prismatic form factors.

Brookfield targets $10 billion of renewable assets under management in India in four years

Brookfield Asset Management targets to more than triple renewable energy assets under management in India to over $10 billion within the next three to four years.

Spontaneous glass breakage on solar panels on the rise

The National Renewable Energy Laboratory noted an increase in spontaneous glass breakage in solar panels. The PV Module Index from the Renewable Energy Test Center investigates this and other glass-related trends in solar manufacturing.