Why do solar power plants work inefficiently?

When choosing a solar power plant, individuals and businesses pay the most attention to its power – after all, this will determine how much electricity will be produced. Other equipment, systems and sensors that allow monitoring and analysis of the operation of the power plant are often underestimated. But they shouldn’t be: the solar power plant will be used for several decades, so various failures and poor-quality monitoring can have a significant impact on the efficiency of electricity production.

Have your say on the future of automation in solar O&M

Cost efficiency while maximizing power output is the name of the game in solar project development and asset management. And the automation of the provision of utility scale solar operations and maintenance (O&M) is fast becoming one of the most compelling opportunities. Help shape the future of automation in solar O&M by completing this first-of-its kind survey.

The long read: Dealing with dust

Sand and dust are a PV plant operator’s worst nightmare. Performance losses due to soiling, or “the dust effect,” are a cause for innovation among O&M providers, particularly in dry and dusty regions that are otherwise ideal locations for large-scale solar installations. Yazeed Al-Mousa examines the latest robotic cleaning solutions, as well as the software and sensors that help plant operators with the tricky economic decision of when to actually start cleaning.

Handheld dry-cleaning tool for solar modules

The handheld, cordless cleaning tool is a cost-effective and efficient alternative to automated cleaning robots that are usually limited in operation by panel inclination.

The long read: The impact of dust on solar panels matters

Anil Kottantharayil currently leads the Centre for Research in Nanotechnology and Science, as well as the Sophisticated Analytical Instrument Facility, at the Indian Institute of Technology (IIT) Bombay. He works on high-efficiency crystalline silicon solar cells, the impact of dust on solar panels, and the long-term reliability of photovoltaic modules.

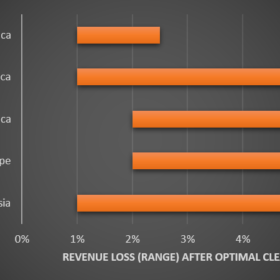

New model to predict PV module cleaning cycles and resulting profits

A group of scientists in Bangladesh has developed a model to determine the optimal cleaning schedule for a PV installation at any location in the globe, requiring only the average insolation and soiling rate for a given site to make the calculation. The study also draws new conclusions regarding the influence of sandstorms and rain on soiling, and aims to be among the first studies to paint a global picture of soiling trends by region.

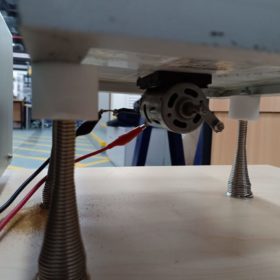

Vibration tech for self-cleaning solar panels

Scientists in the U.K. have developed a system which makes panels vibrate to provide cleaning. The academics have conceded, however, they are yet to calculate the ‘sweet spot’ of mechanical stress to be applied.