From pv magazine 07/2021

pv magazine: What are you seeing in your work as to how PV modules are performing in the field in India?

Anil Kottantharayil: Typically, solar panel manufacturers give nameplate performance guarantees of 80% peak output after 25 years of use. That means there would be a 20% degradation in 25 years, or about 0.8% per year. However, in field surveys conducted by us in 2013, 2014, 2016 and 2018, the overall performance degradation was higher than this. The degradation rate was significantly higher even in the newer modules. The absolute numbers may look quite small, but even minor differences in degradation mean a significant impact on the profitability of the power plant operators over the long term.

Anil Kottantharayil: Typically, solar panel manufacturers give nameplate performance guarantees of 80% peak output after 25 years of use. That means there would be a 20% degradation in 25 years, or about 0.8% per year. However, in field surveys conducted by us in 2013, 2014, 2016 and 2018, the overall performance degradation was higher than this. The degradation rate was significantly higher even in the newer modules. The absolute numbers may look quite small, but even minor differences in degradation mean a significant impact on the profitability of the power plant operators over the long term.

Are soiling losses a big problem?

Unfortunately, we do not have any field reports of the actual soiling losses. The most popular method that people follow is on a reference basis, where you have a set of clean modules and a set of modules that are not cleaned or maybe cleaned once in a week. That way, you’re trying to find out the difference in energy yield.

When we do the surveys, we visit the power plants and do spot measurements after cleaning the panels. But, you need to monitor soiling regularly.

We have a very small solar setup at IIT Bombay rooftop, wherein we have seen fairly high soil accumulation-related losses in the non-rainy season. After October, if you don’t clean the panels, there is 0.4% soiling related loss on the first day, 0.8% on the second day, 1.2% on third day, and so on. So, it’s a 0.4% per day accumulation. This means if you don’t clean the panels in Mumbai, the panel output would be 50% of the name plate due to soling loss, in about 120 days.

What does it take to predict the soiling losses accurately?

I would expect the power plant operators to clean the panels regularly. But then, whether they are doing it in an optimized manner needs to be evaluated. And this is something that cannot be simulated by popular tools for the design and analysis of PV power plants.

So, we did a slightly different thing wherein we did simulations for every day. We developed our own algorithm to use this information which comes from our power plant and PV system, and then combined this information to write a code to predict soiling losses.

For example, we found out that if the panels were cleaned once in seven days, it would lead to about 1% of the energy loss in an entire year in Mumbai. If the cleaning is done once in two weeks, then the loss will increase to 2%, and so on. So, if we cleaned the panels once a month, there would be almost 4% energy loss per year.

Let’s say, I’m making a 10% profit from purely clean panels throughout the year. If I actually clean them only once a month, I will get only 6% profit. Soiling is a very significant issue because it always eats into the top of my revenue from where I will get my profits.

I don’t know whether the industry is doing this kind of analysis. It is actually possible to take out the SCADA data where you have the weather information and solar power plant production data and analyze it to get a good idea about the soiling losses.

What are the areas of research at IIT Bombay?

We have a project funded by India’s Ministry of New and Renewable Energy. It’s called National Centre for Photovoltaic Research and Education (NCPRE). It’s a fairly large activity with the involvement of 29 faculty members from eight departments of the institute. We have about 120 to 130 postgraduate students, including PhD students, also working on these activities.

They research on various aspects of PV such as silicon solar cells, thin-film solar cells, module reliability and energy yield impact due to soiling, storage, and power electronics.

We also have significant education outreach activities, where we try to educate and train industry engineers and researchers on the latest developments in these areas.

Besides, the IIT Bombay setup is also treated as a national facility. So, researchers from other institutions can utilize our facilities to test their work on new materials, for instance.

We do have research programs trying to achieve 21% to 22% in silicon solar cells and even higher efficiencies. There is also an attempt to make tandem solar cells wherein two or more materials with different bandgaps are combined, leading to higher efficiencies. At the same time, the levelized cost of electricity has to be quite competitive. It is essential to develop technologies that can give high efficiency at a low cost.

What role do you see for IIT Bombay in India’s journey to achieving 450 GW of renewable capacity by 2030, including 300 GW of solar capacity?

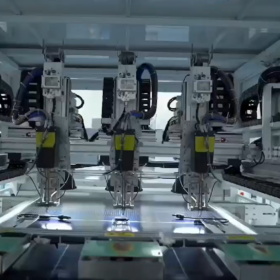

We want to expand our scope of work to essentially facilitate Indian solar cell and module manufacturers in improving their processes and using new materials to improve the reliability of the modules that they produce. We have an industrially compatible academic setup and capabilities for integration of new materials in solar cells and modules. Also, excellent capabilities for detailed analysis of materials, cells and modules are available which can be used for troubleshooting any problems in manufacturing as well as things that impact the long-term reliability of the modules.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Highly new information about efficiency

Iam interested in this up dates of Solar panel s

Currently we maintaining Power plants

The contributions of Prof. Anil is commendable. However, in DST-IIEST Solar PV Hub in IIEST, Shibpur, Howrah, Kolkata India, one researcher recently developed and published a physics based model for assessing the soiling loss on a PV module and validated the same for different plants of different capacities at different geographical locations of India. The researcher has also been invited by PVQAT to present the same in their webinar on 13/7/2021. The researcher is working under the leadership of Professor Hiranmay Saha in the same Hub. Many other researches are going on in this Hub for long time.