India’s 2030 battery gigafactory ambition: Strengths, bottlenecks and solutions

The number of operational battery gigafactories will increase significantly, with more than 30 manufacturing sites expected to be in operation by 2030, targeting a total production capacity exceeding 290 GWh. However, challenges such as raw material and skilled labor shortages, insufficient R&D investment, and a lack of long-term strategic planning remain.

Comparing safety profiles of lithium-ion, sodium-ion and solid-state batteries

New research finds that battery safety rankings are not universal but highly dependent on application scenarios, and shows that LFP batteries can emit high levels of hydrogen fluoride, challenging their reputation as the “safest” chemistry.

Can sodium-ion beat Li-ion in portable power? Bluetti Pioneer Na gives it a try

The world of batteries needs alternative chemistries to skirt weaknesses with lithium-ion. Sodium-ion is a big hope, and in portable power, Bluetti’s new product shows promise, and limitations.

Sodium-ion batteries now competitive in niche markets

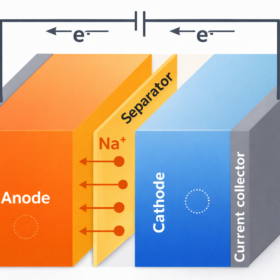

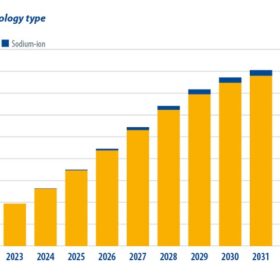

Sodium‑ion batteries are emerging as a safer, lower-cost alternative to lithium‑ion, with a recent international study highlighting their competitiveness in stationary energy storage. The research shows that ongoing investment and supply-chain development could enable broader adoption within the next decade.

Scientists design low-cost sodium-ion battery with cheap electrode materials

Conceived for stationary energy storage, the proposed sodium-ion battery configuration relies on an P2-type cathode material and an hard carbon anode material that reportedly ensure full-cell performance. Electrochemical testing revealed initial capacities of 200 mAh/g for the cathode and 360 mAh/g for the anode with capacity retentions of 42% and 67.4% after 100 cycles.

Why sodium-ion can’t yet challenge lithium-ion’s reign

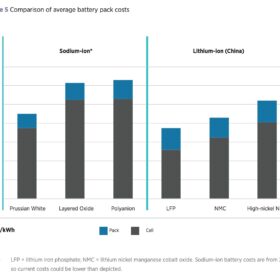

A new generation of sodium-ion (Na-ion) battery cells has been launched as an alternative to the virtual monopoly of lithium-ion (Li-ion). Although the technology is unlikely to displace significant Li-ion market share, recent improvements make Na-ion a viable solution for certain niche applications, with potential for wider usage if cost becomes competitive.

Sodium-ion battery cells already near lithium-ion cost parity, set to get cheaper

By 2050, sodium-ion batteries with fast learning rates could deliver storage at 11–14 €/MWh – cheaper than lithium-ion at 16–22 €/MWh – while also offering higher energy-to-power ratios and high cycle durability, a new research finds.

Europe’s first sodium-ion cell made with fully domestic components

Welsh battery breakthrough uses UK-manufactured anode and cathode materials as well as active materials available through local supply chains. Batri plans to scale up material manufacturing and cell building capability.

Naxion Energy launches India’s first sodium-ion energy storage systems

Naxion Energy (formerly Sodion Energy) has introduced its sodium-ion–based energy storage systems for the residential and commercial & industrial sectors. The storage systems are available in 3.5 kW, 5 kW, and 10 kW models, and the batteries can be expanded to double the system’s storage capacity.

Sodium-ion battery cell cost could drop to $40/kWh, says IRENA

A report from the International Renewable Energy Agency (IRENA) notes that while it is still uncertain whether sodium-ion batteries will become a disruptive alternative to lithium-ion technology, they could offer significant cost-saving opportunities in applications such as electric vehicles and large-scale energy storage.