Solar panel recycling plan urges repair, reuse first

Australia’s rooftop solar industry has renewed calls for a mandatory recycling scheme to deal with the growing problem of solar panel waste. Only about 10% of panels are currently recycled. The rest are stockpiled, sent overseas or dumped in landfill.

ReNew Q4 profit soars 415% YoY on solar manufacturing boost

ReNew’s net profit for the quarter ended March 31, 2025 surged 415% year-on-year to INR 313.7 crore ($37 million) with external sales of solar modules and cells alone contributing INR 220 crore.

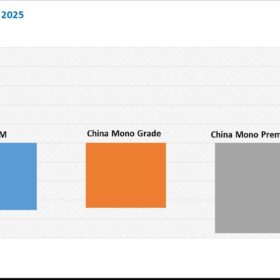

China polysilicon prices fall 11.76% since early April peak

In a new weekly update for pv magazine, OPIS, a Dow Jones company, reports thatglobal polysilicon negotiations remain challenging, as buyers and sellers continue to struggle to reach agreements on pricing amid a persistent supply-demand imbalance. Furthermore, it reveals that China’s polysilicon futures market could imply a further 13% drop for Nov 2025 delivery contracts.

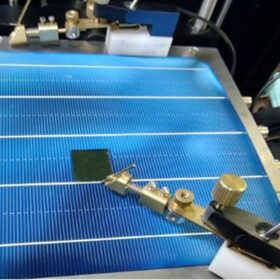

TNO, Solarge unveil lightweight perovskite solar module prototype

TNO and Solarge have developed a lightweight perovskite solar module prototype measuring 32 cm x 34 cm by combining roll-to-roll processing and low-weight panel materials. The Netherlands-based partners aim to scale the technology for broader commercial applications.

Ahaan Solar advances 2 GW solar module factory in Haryana

Utilizing advanced tunnel oxide passivated contact (TOPCon) technology, Ahaan Solar’s factory in Haryana will produce high-efficiency solar modules for both domestic and international markets.

Longi unveils 700 W back-contact PV panel with world record silicon solar cell

Chinese solar manufacturer Longi unveiled a new PV module with 25.9% efficiency at the 2025 SNEC trade show this week in Shanghai, produced using both low- and high-temperature passivation techniques.

Why LFP batteries are gaining traction in India’s EV ecosystem

Leading EV manufacturers and battery suppliers in India are increasingly adopting Lithium Iron Phosphate (LFP) battery technology for entry-level and mid-range EVs. This is due to a balance of cost, safety, and durability that fits the Indian market’s practical needs.

Reliance Industries Ltd enters ALMM list with high-efficiency HJT solar modules

Reliance Industries Ltd (RIL) has been included in the Ministry of New and Renewable Energy’s (MNRE) Approved List of Models and Manufacturers (ALMM) with its high-efficiency heterojunction (HJT) solar modules, featuring efficiencies of up to 23.12%.

Indian scientists build 29.14%-efficient tandem solar cell with inverted top perovskite device

The researchers said they optimized the low-bandgap inverted perovskite cells through a passivating aluminum oxide (Al2O3) interlayer deposited via atomic layer deposition (ALD), which significantly helped improve device efficiency.

2025: A landmark year for solar energy

The IEA-PVPS 2025 Snapshot of Global PV Markets reveals a pivotal moment for solar power: global PV capacity surpassed 2.2 TW, with more than 600 GW installed in 2024 alone. As module prices fell due to oversupply, installation volumes continued to grow, highlighting both the strength and volatility of the global PV industry.