Goldi Solar to expand manufacturing capacity to 2.5 GW with new facility

The Indian solar panel manufacturer is setting up a 2 GW facility in Surat, increasing its total manufacturing capacity from 500 MW at present to 2.5 GW. The new facility will implement micro-gap module technology (MGMT), and produce high-efficiency mono-facial and bifacial modules with peak power output exceeding 500W and 600W, respectively.

New process to recycle silicon, silver and glass from end-of-life PV panels

A €4.8 million EU-funded research project is aiming to develop a process that allows recovering all components of a photovoltaic module.

Amara Raja Batteries to reposition itself as an energy and mobility player

The Indian lead-acid battery major would form a new strategic business unit for lithium cells and battery packs, electric vehicle (EV) chargers, energy storage systems, and other related products and services as it looks to reposition itself as an energy and mobility player.

The long read: Dial manganese for battery stability

Often sidelined by nickel and cobalt when it comes to batteries, the metal manganese is finding proponents in science and industry – in particular, by those attempting to avoid supply and cost issues. Ian Morse reports on the role of manganese in battery cell production.

Surge in solar panel and polysilicon prices may impact projects in India

Modules represent 45 to 55% of the project capex. In a very competitive market like India, independent power producers have lower margins, and even a modest increase in module prices will put more pressure on them.

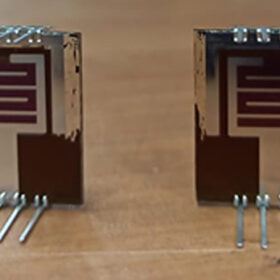

Smart sticker for smart solar modules

The sticker is based on a blockchain technology developed by German start-up Authentic Network. Meyer Burger uses the application for the photovoltaic modules it produces in its new factory that opened in Freiberg at the end of May.

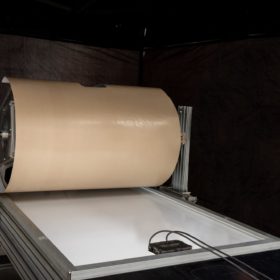

A repair tape for cracked backsheets

Backsheet failures have plagued the industry, causing hefty financial burdens to many asset owners. DuPont has launched a product it says allows for easy repair of modules.

Solex orders 1.2 GW solar module production line

The Gujarat-based solar panel maker will buy the production equipment from China’s Jinchen Machinery. Solex also has plans for a 1 GW cell line.

Longi achieves 25.21% efficiency for TOPCon solar cell

The Chinese module manufacturer said the result was confirmed by the Institute for Solar Energy Research in Hamelin, Germany.

Nano-micro-scale cooler for solar modules

The proposed technique is based on radiative cooling and consists of a glass coating made with a two-dimensional subwavelength nanostructured grating, which is imprinted in soda-lime glass and has enhanced mid-infrared emissivity, and a micro-structured grating. The temperature decrease provided by the nano-micro-grating coating was found to be approximately up to 5.8 degrees Celsius.