The PV industry needs 12 times more polysilicon production capacity by 2050

New research from the University of New South Wales (UNSW) predicts cumulative polysilicon demand of 46-87 Mt will be required to achieve 63.4 TW of PV installed by 2050.

Goldi Solar supplies 9+ MW PV panels to Odisha project

The Gujarat-based solar manufacturer has entered the Odisha market by completing the supply of 9+ MW PV panels for a PV project in the state.

Reliance, Ola, Rajesh Exports sign agreement to make batteries under PLI Scheme

The three companies will receive incentives under the government’s production-linked incentives scheme for battery storage. The scheme has an overall budgetary outlay of INR 18,100 crore (around US$ 2,284 million).

Cooling down solar modules with cotton wicks immersed in water

The novel technique consists of attaching cotton wicks immersed in the water (CWIWs) to the backside photovoltaic module. The water is supplied to cotton wicks from top to bottom by gravity which the scientists said helps the effective absorption of cotton and reduces water consumption.

India may fall behind its 2030 EV sales forecast

A new report says India will have only 50 million electric vehicles (EVs) on road by 2030 despite a ramp-up in domestic manufacturing, falling behind by 40% on the cumulative sales projections by NITI Aayog. It also recommends policy measures to improve India’s chances of realizing 80 million EV sales by 2030.

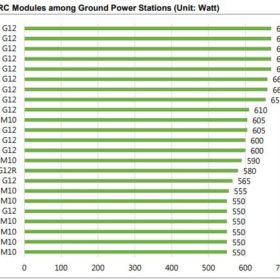

Solar panel sizes continue to get larger and improve LCOE, says TrendForce report

A new report from the Taiwanese market research company shows growth in the production of modules over 600 W and increased format size. Cells and wafers are getting larger as well.

TERI draws up roadmap to India’s 2030 renewable energy goal

A new report by The Energy and Resources Institute (TERI) examines the challenges before India in achieving its ambitious target of having 500 GW non-fossil fuel capacity and meeting 50% of its energy requirements from renewables by 2030. It also discusses feasible pathways for achieving these.

Trina Solar surpasses 8 GW of PV module shipments to India

The Chinese PV module maker has shipped more than 8 GW of solar panels to India since the start of its operations in the market in 2010.

Comparing performance of transparent solar windows to traditional windows

The results of the study by Wells Fargo Foundation and NREL initiative showed that PV-coated windows can appreciably lower the solar heat gain coefficient.

Flasher for a solar PV lab

Sun simulator is considered to be the heart of a testing or a calibration lab used to test solar PV panels, indoor under controlled and repeatable conditions. There are various parameters to be considered while selecting one.